filmov

tv

Bladeless Turbine built by Nikola Tesla #tesla #engineering #science

Показать описание

@CharlieSolis

TesTur Energy Tesla Turbine:

Use “Integza5” to get $50 off your turbine!

TesTur Energy Tesla Turbine:

Use “Integza5” to get $50 off your turbine!

Bladeless Turbine built by Nikola Tesla #tesla #engineering #science

Building Nikola Tesla's Bladeless Turbine

Tesla Turbine | The interesting physics behind it

How Fast Can a Tesla Turbine Spin?

Building Tesla's Bladeless Turbine

TESLA TURBINE | What happened?

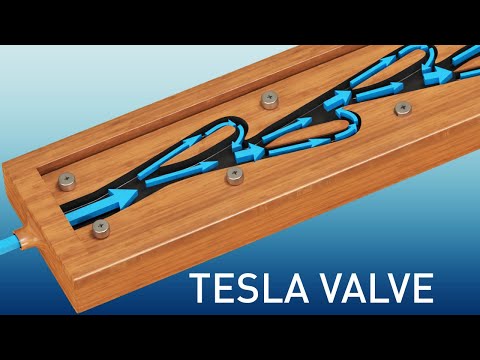

Tesla Valve | The complete physics

1888 Rethinking The Tesla Turbine For Wind Power

Genius Bladeless Hydro Turbine is Cheaper Than Solar

how a vortex bladeless wind turbine works #cleanenergyfuture #renewable #windpower #vortexbladeless

Tesla. Truly One of The Greatest Inventors of All Time.

Tesla's Bladeless Turbine: The Tech That Could've Changed the World

20 Scariest Inventions By Nikola Tesla Hidden From US!

The Nikola Tesla Turbine Is Reversible in 2 Ways

Tesla Turbine + Chuck Norris

What will you do to make it? - Tesla Turbine R&D

Nikola Tesla Turbines

A Tesla Turbine That Actually Works!

Top 3 Nikola Tesla Inventions

Nikola Tesla Teaching Engineers How His Turbine Works

The Revolutionary Inventions of Nikola Tesla Bladeless Turbine and Robotics

A Nikola Tesla Turbine That Actually Works!?!

If your engine don’t look like that, you better...! - Tesla Turbine Jet Engine Research Development...

Tesla turbine.

Комментарии

0:00:59

0:00:59

0:12:36

0:12:36

0:09:24

0:09:24

0:05:33

0:05:33

0:01:00

0:01:00

0:11:52

0:11:52

0:06:02

0:06:02

0:05:16

0:05:16

0:10:13

0:10:13

0:00:17

0:00:17

0:01:00

0:01:00

0:00:48

0:00:48

0:21:35

0:21:35

0:00:41

0:00:41

0:00:20

0:00:20

0:00:25

0:00:25

0:03:22

0:03:22

0:00:27

0:00:27

0:00:15

0:00:15

0:00:35

0:00:35

0:00:49

0:00:49

0:00:11

0:00:11

0:00:06

0:00:06

0:01:01

0:01:01