filmov

tv

PLC Ladder Program: OR and NOT Logic with Real-World Examples | Automation and PLC Series Part 5

Показать описание

Welcome back to our Automation and PLC Series! 🎉

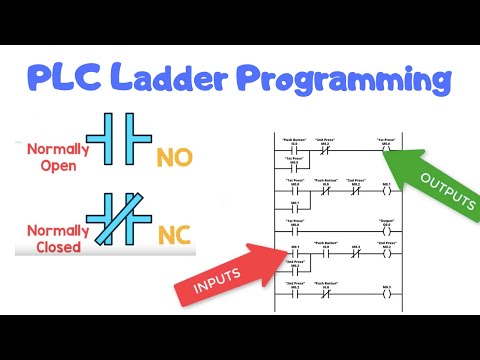

In Part 5, we continue our deep dive into PLC Ladder Programming, focusing on implementing OR and NOT Boolean logic using NO (Normally Open) and NC (Normally Closed) contacts. Building on the concepts from our previous video, we bring these logic gates to life through practical, real-world examples.

🔹 What You'll Learn:

• Understanding OR and NOT Logic in PLCs:

o Learn how to implement OR and NOT Boolean logic using ladder programming.

o Understand the role of NO and NC contacts in creating these logic functions.

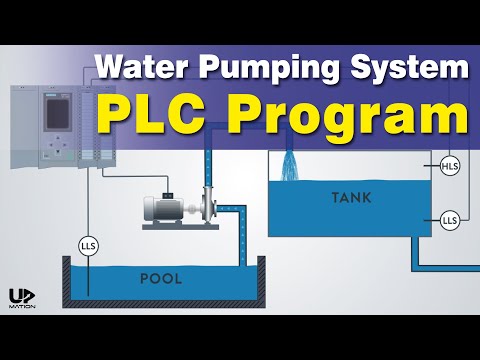

• Real-World Application in the Food Processing Industry:

o Scenario 1: How to raise an alarm if any of the two food processing machines fail (OR logic).

o Scenario 2: How to stop the conveyor system when any machine stops, ensuring safety and efficiency.

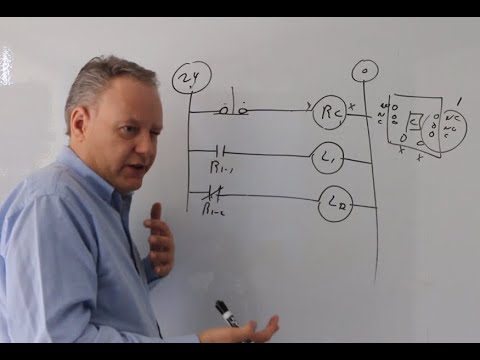

• Step-by-Step Programming:

o Follow along as we develop the ladder logic diagrams for these scenarios.

o See how ladder programming simplifies complex automation tasks.

🔧 Key Concepts Covered:

• PLC Ladder Programming Basics

• Implementing OR Logic with NO Contacts

• Implementing NOT Logic with NC Contacts

• Developing Control Logic for Automation

• Practical Use of Logic Gates in Industrial Automation

👉 Why Watch This Video?

This video is perfect for beginners and intermediate learners aiming to enhance their understanding of PLC programming and industrial automation. By the end of this tutorial, you'll be able to apply OR and NOT logic in ladder programming to solve real-world automation challenges.

🔔 Stay Tuned:

In upcoming videos, we'll explore more complex logic implementations and delve deeper into the world of PLC programming.

👍 Don't Forget to Like, Share, and Subscribe!

Help us spread knowledge by sharing this video with fellow engineering enthusiasts!

________________________________________

📢 Join the Conversation:

Have questions or topics you'd like us to cover? Drop a comment below! We're here to support your learning journey in engineering and automation.

________________________________________

#PLCLadderProgramming #ORLogic #NOTLogic #PLC #ProgrammableLogicController #IndustrialAutomation #AutomationSeries #EngineeringEducation #NOandNCContacts #ControlLogic #PLCProgramming #EngineeringConcepts #2DAnimation #AutomationTutorial #ElectricalEngineering #ControlSystems #EngineeringForBeginners #FunEngineering #EducationalAnimation

________________________________________

----------------------------------------------------

Introduction to PLC | Programmable logic controllers | Steps towards learning Automation - 01

How does a relay work? | Normally Open | Normally Closed | Steps towards learning Automation - 02

Concept of Sinking and Sourcing in PLC | Steps towards learning Automation - 03

PLC Ladder programming #1 | NO NC contacts | AND gate logic | Steps towards learning Automation - 04

-----------------------------------------------------

Link to the video on Derived gates:

Link to our video on Boolean algebra

Link to previous videos on Gates:

on Double Beam Spectrometer

on Basics and principle of Fluorescence & Phosphorescence measurement in Analytical Instrumentation

on Basics of UV-Vis spectroscopy in Analytical Instrumentation

on Filters and Monochromators, Gratings used in Analytical Instrumentation

-------------------------------------------------------------------------------------------

Check our playlist on Digital Electronics:

Check our playlist on Analytical Instrumentation:

-------------------------------------------------------------------------------------------

Follow us on:

----------------------------

In Part 5, we continue our deep dive into PLC Ladder Programming, focusing on implementing OR and NOT Boolean logic using NO (Normally Open) and NC (Normally Closed) contacts. Building on the concepts from our previous video, we bring these logic gates to life through practical, real-world examples.

🔹 What You'll Learn:

• Understanding OR and NOT Logic in PLCs:

o Learn how to implement OR and NOT Boolean logic using ladder programming.

o Understand the role of NO and NC contacts in creating these logic functions.

• Real-World Application in the Food Processing Industry:

o Scenario 1: How to raise an alarm if any of the two food processing machines fail (OR logic).

o Scenario 2: How to stop the conveyor system when any machine stops, ensuring safety and efficiency.

• Step-by-Step Programming:

o Follow along as we develop the ladder logic diagrams for these scenarios.

o See how ladder programming simplifies complex automation tasks.

🔧 Key Concepts Covered:

• PLC Ladder Programming Basics

• Implementing OR Logic with NO Contacts

• Implementing NOT Logic with NC Contacts

• Developing Control Logic for Automation

• Practical Use of Logic Gates in Industrial Automation

👉 Why Watch This Video?

This video is perfect for beginners and intermediate learners aiming to enhance their understanding of PLC programming and industrial automation. By the end of this tutorial, you'll be able to apply OR and NOT logic in ladder programming to solve real-world automation challenges.

🔔 Stay Tuned:

In upcoming videos, we'll explore more complex logic implementations and delve deeper into the world of PLC programming.

👍 Don't Forget to Like, Share, and Subscribe!

Help us spread knowledge by sharing this video with fellow engineering enthusiasts!

________________________________________

📢 Join the Conversation:

Have questions or topics you'd like us to cover? Drop a comment below! We're here to support your learning journey in engineering and automation.

________________________________________

#PLCLadderProgramming #ORLogic #NOTLogic #PLC #ProgrammableLogicController #IndustrialAutomation #AutomationSeries #EngineeringEducation #NOandNCContacts #ControlLogic #PLCProgramming #EngineeringConcepts #2DAnimation #AutomationTutorial #ElectricalEngineering #ControlSystems #EngineeringForBeginners #FunEngineering #EducationalAnimation

________________________________________

----------------------------------------------------

Introduction to PLC | Programmable logic controllers | Steps towards learning Automation - 01

How does a relay work? | Normally Open | Normally Closed | Steps towards learning Automation - 02

Concept of Sinking and Sourcing in PLC | Steps towards learning Automation - 03

PLC Ladder programming #1 | NO NC contacts | AND gate logic | Steps towards learning Automation - 04

-----------------------------------------------------

Link to the video on Derived gates:

Link to our video on Boolean algebra

Link to previous videos on Gates:

on Double Beam Spectrometer

on Basics and principle of Fluorescence & Phosphorescence measurement in Analytical Instrumentation

on Basics of UV-Vis spectroscopy in Analytical Instrumentation

on Filters and Monochromators, Gratings used in Analytical Instrumentation

-------------------------------------------------------------------------------------------

Check our playlist on Digital Electronics:

Check our playlist on Analytical Instrumentation:

-------------------------------------------------------------------------------------------

Follow us on:

----------------------------

Комментарии

0:06:35

0:06:35

0:04:45

0:04:45

0:03:58

0:03:58

0:10:53

0:10:53

0:02:44

0:02:44

0:03:48

0:03:48

0:11:16

0:11:16

0:05:40

0:05:40

0:07:00

0:07:00

0:06:38

0:06:38

0:09:46

0:09:46

0:11:22

0:11:22

0:07:03

0:07:03

0:05:33

0:05:33

0:24:20

0:24:20

0:04:48

0:04:48

0:33:09

0:33:09

0:09:04

0:09:04

0:09:37

0:09:37

0:05:57

0:05:57

0:23:48

0:23:48

0:15:11

0:15:11

0:06:25

0:06:25

0:03:18

0:03:18