filmov

tv

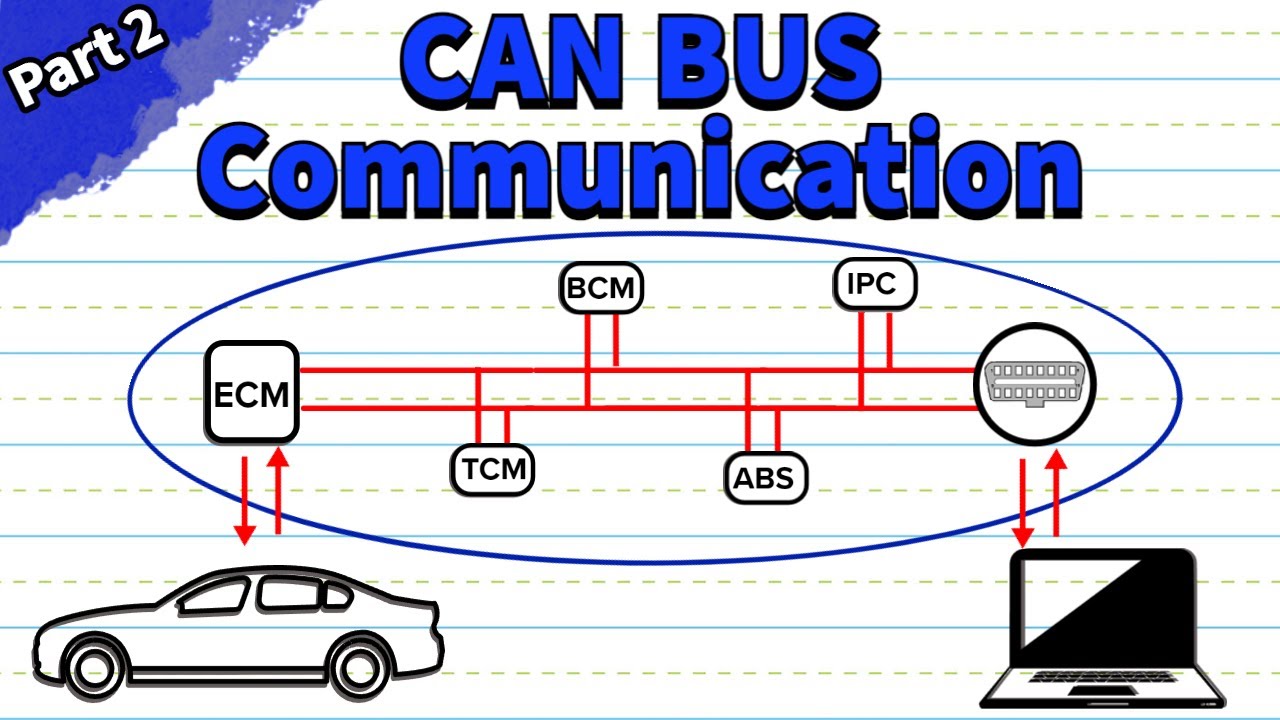

CAN Bus Wiring and Protocol Explained (Part 2)

Показать описание

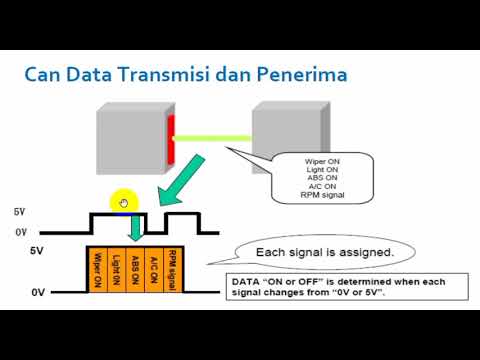

"How a communication bus is wired determines how you diagnose it!" In the second part of this three part series, we dive deeper into CAN Bus wiring and how to breakdown networks even further. While still taking a real world approach we will discuss the differences in network topology and the protocols used to speak on them.

#cars #learning #autorepair #diy #fixed

#cars #learning #autorepair #diy #fixed

CAN Bus: A Beginners Guide Part 1

CAN Bus Wiring and Protocol Explained (Part 2)

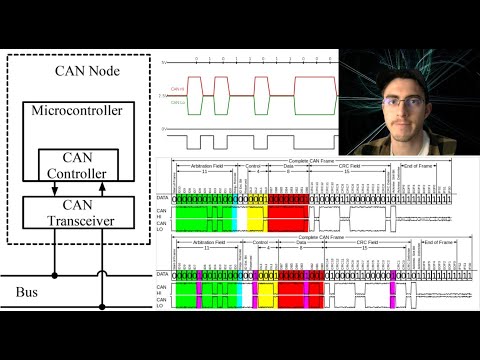

CAN Bus: Serial Communication - How It Works?

CAN Bus Communication Explained (Part 1)

CAN Protocol Explained | Controller Area Network

Explained! CAN BUS Diagnosis – How to Troubleshoot Faults.

CAN Bus Properties and Troubleshooting

CAN Bus Explained - A Simple Intro [v1.0 | 2019]

CAN-BUS Explained | Everything You Need to Know About CAN-BUS | CAN-Bus Diagnostics & How It Wor...

Splicing Into A CAN Bus Network | CAN Bus Communications [FREE LESSON]

CAN Bus Explained - A Simple Intro [v2.0 | 2021] 🌟

Test CAN BUS With a Multimeter | Quick & Easy | CAN Bus Resistance, Voltage & Short to Groun...

CAN Bus communication explained in 5 minutes

Reading an Existing CAN Bus Network | CAN Bus Communications [FREE LESSON]

Introduction to the Controller Area Network (CAN)

Can bus wiring with Sienna!

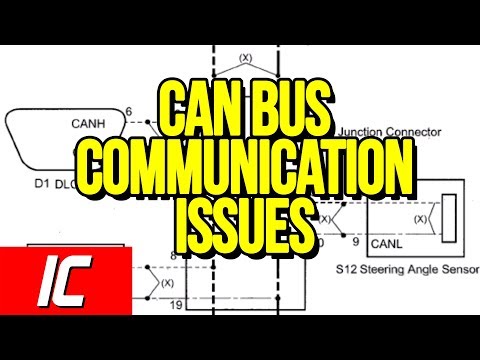

CAN bus communication issues | Tech Minute

CAN-BUS Diagnostics | Diagnosing CAN BUS with an Oscilloscope #canbus #oscilloscope

CAN BUS SISTEM

What is CAN Bus? | CAN Communications

CAN Bus: A Beginners Guide Part 2

MCP2515 CAN Controller Demo CAN BUS Protocol Diagnostic Tool

CAN Bus System Explained

How to test a CAN bus network with a meter

Комментарии

0:37:36

0:37:36

0:47:10

0:47:10

0:11:25

0:11:25

0:33:44

0:33:44

0:12:09

0:12:09

0:11:49

0:11:49

0:18:09

0:18:09

0:08:42

0:08:42

0:33:53

0:33:53

0:13:19

0:13:19

0:14:44

0:14:44

0:06:33

0:06:33

0:05:32

0:05:32

0:11:31

0:11:31

0:03:49

0:03:49

0:00:47

0:00:47

0:02:49

0:02:49

0:06:41

0:06:41

0:08:25

0:08:25

0:05:35

0:05:35

0:31:44

0:31:44

0:00:09

0:00:09

0:09:21

0:09:21

0:16:07

0:16:07