filmov

tv

AC Frequency Made Simple: Primeweld TIG 225x Tutorial

Показать описание

New products being added weekly.

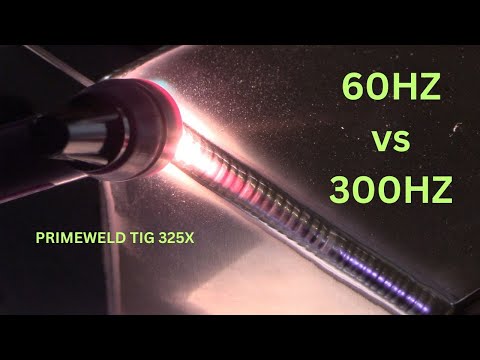

To show the affects on AC frequency, I stacked several beads using different frequencies from 40hz to 200hz.

100-120hz is a good all around setting but I like to lower the frequency for thicker metal or when I want a fat bead.

Higher AC frequency settings help focus the arc cone for a pinpointed arc.

Join the discussion with thousands of welders at the Welding Tips & Tricks forum

AC Frequency Made Simple: Primeweld TIG 225x Tutorial

PrimeWeld TIG325X Comparing AC Frequency Settings

AC Balance Unleashed: Maximizing TIG Welding Performance on PrimeWeld TIG225

Simple TIG Settings PrimeWeld 225

🔥AC Frequency vs. AC Balance (Aluminum TIG Welding)

TIG Welding Aluminum and the Differences in AC Frequency Settings

PrimeWeld TIG325x, AC Frequencies, & Clear Cups

TIG AC Frequency Adjustment | Everlast Welders

PrimeWeld TIG325X, Razor Blades, and 1/4' Aluminum

TFS: Understanding AC Balance #TIGSimple

TFS: Primeweld TIG225 AC/DC

Weld With Me LIVE Setup (here's your settings)

Stop doing this to yourself tig welding! Follow this tip! #shorts

7 Tips for TIG welding Aluminum

the 3 BEST SETTINGS to start tig welding

How to weld 2 cans together with the Prime Weld Tig 225x

How to turn your Mig Welder into a Tig Welder (PrimeWeld)

the DEFINITIVE GUIDE TO TIG WELDING BALANCE -How to TIG weld aluminum

Pulse Welding For Beginners ( Explained ) Primeweld 225.

Primeweld 325x Reviewed and Compared

PrimeWeld TIG225x 4130, Sanitary Stainless, and Aluminum

This is what high frequency does on a tig welding machine #welding #shorts

Beginner Tig welding Settings

PrimeWeld TIG225X 2T and 4T Settings - Switch vs Foot Pedal

Комментарии

0:05:55

0:05:55

0:05:39

0:05:39

0:05:14

0:05:14

0:21:48

0:21:48

0:18:12

0:18:12

0:05:31

0:05:31

0:08:54

0:08:54

0:07:05

0:07:05

0:06:18

0:06:18

0:11:23

0:11:23

0:22:15

0:22:15

0:09:24

0:09:24

0:00:59

0:00:59

0:05:22

0:05:22

0:12:11

0:12:11

0:00:40

0:00:40

0:08:30

0:08:30

0:11:24

0:11:24

0:14:53

0:14:53

0:16:09

0:16:09

0:03:49

0:03:49

0:00:24

0:00:24

0:11:40

0:11:40

0:11:57

0:11:57