filmov

tv

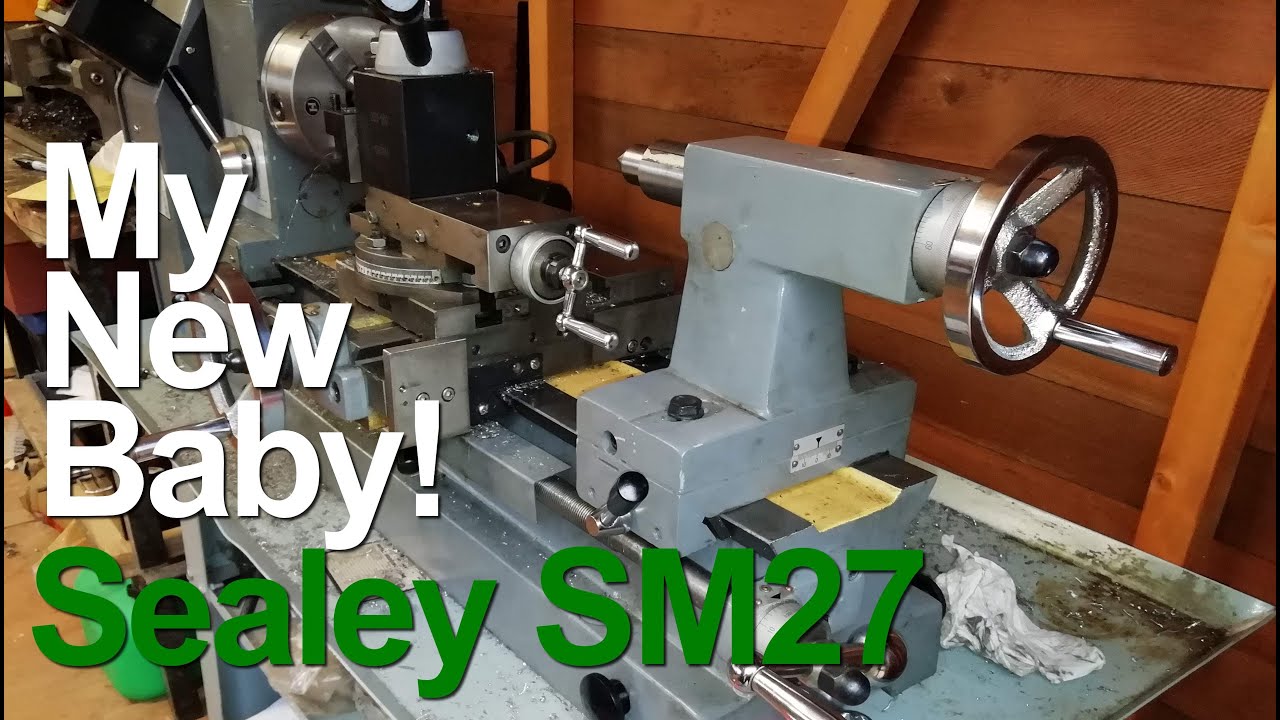

Review of my New Sealey SM27 Metal Lathe (also badged by Clarke & Warco)

Показать описание

A metal lathe is central to any metal wortking machine shop.

I have lost access to my brother's lathe - which is what I have been using to make my plastric injection molders. So I decided to buy a second-hand lathe on EBay.

This is my initial review of that lathe.

I bought this Sealey SM27 metal lathe locally. This is a Chinese lathe, also badged as the Clarke CL430 and Warco also badged a version with a milling head.

The lathe currently retails from £12,00 to "1,800 new. I paid £565 at auction, but with that I also got the steel stand, an upgraded quick-change tool post steady rest, rotary table, Colette chuck, an as-new 4-jaw chuck, lots of as-new cutting tools with many spare inserts, a no-key tail stock chuck and some HSS tooling blanks.

The lathe operates wonderfully. It feels more solid than the more modern lathe I've been using, and it can take 1mm cuts in stainless steel on auto-feed without a murmur. It might do better - I haven't found it's boundaries yet.

Downsides? Well, there are a few:

1. It's a manual speed change involving moving belts on pullies which take time.

2. The saddle is moved up & down the bed with a handle on the leadscrew. This makes it very solid (the other lathe would wander on a heavy cut unless locked) but it takes an age to move the saddle form one end of the bed to the other. There is no half-nut. Turning must be done when standing close to the tailstock end of the lathe in order to reach the handle.

3. The screw-cutting gear set - 13 wheels - was not included and will cost £180 + VAT new.

4. There is no rule on the tailstock.

Still, so far, I'm very pleased with it, and I've already used it to machine the beefy stainless steel parts for my next plastic injection moulding machine.

Next step is to fit a modified digital caliper for a tail scale.

After that DROs.

Subscribe to see those.

SAY THANKS WITH PATREON:

MUSIC:

I have lost access to my brother's lathe - which is what I have been using to make my plastric injection molders. So I decided to buy a second-hand lathe on EBay.

This is my initial review of that lathe.

I bought this Sealey SM27 metal lathe locally. This is a Chinese lathe, also badged as the Clarke CL430 and Warco also badged a version with a milling head.

The lathe currently retails from £12,00 to "1,800 new. I paid £565 at auction, but with that I also got the steel stand, an upgraded quick-change tool post steady rest, rotary table, Colette chuck, an as-new 4-jaw chuck, lots of as-new cutting tools with many spare inserts, a no-key tail stock chuck and some HSS tooling blanks.

The lathe operates wonderfully. It feels more solid than the more modern lathe I've been using, and it can take 1mm cuts in stainless steel on auto-feed without a murmur. It might do better - I haven't found it's boundaries yet.

Downsides? Well, there are a few:

1. It's a manual speed change involving moving belts on pullies which take time.

2. The saddle is moved up & down the bed with a handle on the leadscrew. This makes it very solid (the other lathe would wander on a heavy cut unless locked) but it takes an age to move the saddle form one end of the bed to the other. There is no half-nut. Turning must be done when standing close to the tailstock end of the lathe in order to reach the handle.

3. The screw-cutting gear set - 13 wheels - was not included and will cost £180 + VAT new.

4. There is no rule on the tailstock.

Still, so far, I'm very pleased with it, and I've already used it to machine the beefy stainless steel parts for my next plastic injection moulding machine.

Next step is to fit a modified digital caliper for a tail scale.

After that DROs.

Subscribe to see those.

SAY THANKS WITH PATREON:

MUSIC:

Комментарии

0:08:00

0:08:00

0:21:48

0:21:48

0:05:08

0:05:08

0:02:11

0:02:11

0:00:14

0:00:14

0:05:11

0:05:11

0:00:46

0:00:46

0:03:50

0:03:50

0:06:57

0:06:57

0:08:00

0:08:00

0:01:13

0:01:13

0:06:40

0:06:40

0:02:25

0:02:25

0:00:23

0:00:23

0:02:34

0:02:34

0:00:15

0:00:15

0:00:47

0:00:47

0:07:04

0:07:04

0:01:32

0:01:32

0:00:26

0:00:26

0:08:36

0:08:36

0:02:14

0:02:14

0:01:50

0:01:50

0:05:39

0:05:39