filmov

tv

How to build a workbench - (Part 1) Laminating the top | Paul Sellers

Показать описание

Want to know how to build a workbench without a workbench? This is a somewhat difficult part of getting into woodworking that Paul Sellers addresses in this video. In part 1, Paul Sellers shows how to laminate (glue up) several smaller boards to make up the top of the bench. All done in his garden to show how you can make it without a workshop.

How To Build A Workbench - The Best Way

Building a Workbench With Storage in Less Than One Hour - Only One Plywood Sheet and Some 2x4's

How to Build an Easy, Sturdy Workbench

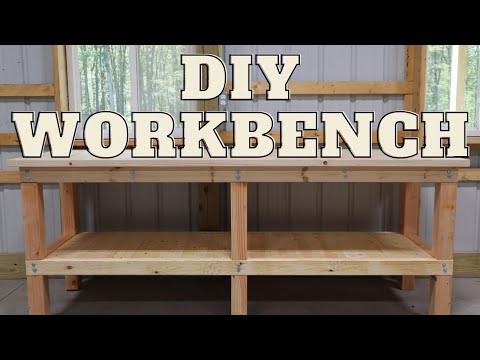

How To Build A Workbench For Your Garage | Easy 2x4 DIY!

EASY Beginner Basic Tool Workbench Build!

How To Build a Simple Cheap Work Bench

The PERFECT Woodworking Workbench // How To Build The Ultimate Hybrid Workholding Bench

DIY 2x4 Workbench for Under $100 | Modern Builds | Woodworking

Vevor Work Bench Review#value #sales #tools #diy #viralvideo

HOW TO BUILD A WORKBENCH FOR GARAGE / DIY Garage Workbench and Shelves

EASY DIY WORKBENCH for UNDER $50

How to Build a Workbench - Ep.1

Building a Sturdy Workbench with Cheap Wood

Don't Make a 2x4 Workbench

Can Your Workbench Do This?

The Minimum Timber Bench // Start woodworking for less!

Build This Workbench for UNDER $200

How to Build a Cheap and Strong Workbench with FREE plans

Modular Workbench for Beginners

Watch This Before Building Your Workbench

I Built The Ultimate FIRST Workbench.

DIY BUDGET FRIENDLY WORKBENCH (FREE DOWNLOADABLE PLANS)

How to make A Workbench | DIY WOODWORKING

How to Build a Workbench | Mitre 10 Easy As DIY

Комментарии

0:11:43

0:11:43

0:05:32

0:05:32

0:14:02

0:14:02

0:10:45

0:10:45

0:09:53

0:09:53

0:04:14

0:04:14

0:13:10

0:13:10

0:16:10

0:16:10

0:05:15

0:05:15

0:13:36

0:13:36

0:06:10

0:06:10

0:16:25

0:16:25

0:19:53

0:19:53

0:18:18

0:18:18

0:00:44

0:00:44

0:08:31

0:08:31

0:12:38

0:12:38

0:07:46

0:07:46

0:15:13

0:15:13

0:17:23

0:17:23

0:19:18

0:19:18

0:05:48

0:05:48

0:16:25

0:16:25

0:07:57

0:07:57