filmov

tv

Electric Motor Types : Used In Electric Vehicles

Показать описание

Brushless DC Motor

It is called brushless because it does not have the commutator and brush arrangement. The commutation is done electronically in this motor because of this BLDC motors are maintenance free. BLDC motors have traction characteristics like high starting torque, high efficiency around 95-98%, etc. BLDC motors are suitable for high power density design approach. The BLDC motors are the most preferred motors for the electric vehicle application due to its traction characteristics. You can learn more about BLDC motors by comparing it with normal brushed motor.

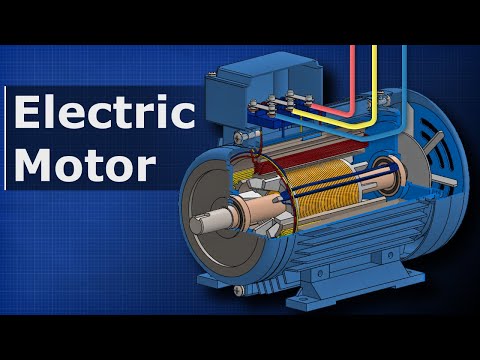

AC Induction Motor

The AC Induction Motor (ACIM) is the workhorse of the motor world. It is the most common motor type, used in everything from consumer products to heavy industry and electric vehicles . Its simple design with no brushes makes it highly reliable and allows it to be manufactured at a low cost. However, it is less efficient than other motors like the Permanent Magnet Synchronous Motor (PMSM), which is partially related to the heat generation in the rotor windings.

Permanent Magnet Synchronous Motor

Permanent Magnet Synchronous Motors (PMSMs) are brushless and have very high reliability and efficiency. Due to their permanent magnet rotor, they also have higher torque with smaller frame size and no rotor current, all of which are advantages over AC Induction Motors (AICMs). With their high power-to-size ratio, PMSMs can help make your design smaller without the loss of torque. PMSMs need to be commutated like BLDC motors, but due to the construction of the windings, the waveforms need to be sinusoidal for good performance.

Interior Permanent Magnet Motor

A type of motor that has a rotor embedded with permanent magnets is called the IPM (interior permanent magnet) type. Compared with the SPM (surface permanent magnet), this type of motor can reduce the risk of a magnet being peeled off by centrifugal force, and take advantage of reluctance torque. The IPM type allows various structures for embedding permanent magnets.

Permanent Magnet Synchronous Reluctance Motor

Permanent Magnet Synchronous Reluctance Motors are receiving much attention due to their high speed, power density and efficiency characteristics. The permanent magnets made of rare earth and neodymium have lower inertia compared with Induction Motor because of elimination of rotor cage. Hence torque to inertia ratio of PMSRM is higher. As PMSRM has negligible rotor losses, their efficiency is high. PMSRM has the excitation in the form of the rotor magnet, hence no external source of magnetizing current for excitation is required like an induction motor. Since rotor losses in PMSRM is small, the loss in the form of heat is avoided which improves the performance of the motor. PMSRM is smaller in size and has lesser weight. It is suitable for the applications where the size of machine is limited.

Top 12 Upcoming Electric Bikes In India 2021

Top 15 Upcoming Electric Scooters In India 2020 - 21

Disclaimer- some contents are used for educational purposes under fair use. Copyright disclaimer under section 107 of the Copyright Act 1976, allowance is made for "fair use" for purposes such as criticism, news reporting, teaching, scholarship, and research. Fair use is a use permitted by copyright statute that might otherwise be infringing. Non-profit, educational or personal use tips the balance in favor of fair use.

It is called brushless because it does not have the commutator and brush arrangement. The commutation is done electronically in this motor because of this BLDC motors are maintenance free. BLDC motors have traction characteristics like high starting torque, high efficiency around 95-98%, etc. BLDC motors are suitable for high power density design approach. The BLDC motors are the most preferred motors for the electric vehicle application due to its traction characteristics. You can learn more about BLDC motors by comparing it with normal brushed motor.

AC Induction Motor

The AC Induction Motor (ACIM) is the workhorse of the motor world. It is the most common motor type, used in everything from consumer products to heavy industry and electric vehicles . Its simple design with no brushes makes it highly reliable and allows it to be manufactured at a low cost. However, it is less efficient than other motors like the Permanent Magnet Synchronous Motor (PMSM), which is partially related to the heat generation in the rotor windings.

Permanent Magnet Synchronous Motor

Permanent Magnet Synchronous Motors (PMSMs) are brushless and have very high reliability and efficiency. Due to their permanent magnet rotor, they also have higher torque with smaller frame size and no rotor current, all of which are advantages over AC Induction Motors (AICMs). With their high power-to-size ratio, PMSMs can help make your design smaller without the loss of torque. PMSMs need to be commutated like BLDC motors, but due to the construction of the windings, the waveforms need to be sinusoidal for good performance.

Interior Permanent Magnet Motor

A type of motor that has a rotor embedded with permanent magnets is called the IPM (interior permanent magnet) type. Compared with the SPM (surface permanent magnet), this type of motor can reduce the risk of a magnet being peeled off by centrifugal force, and take advantage of reluctance torque. The IPM type allows various structures for embedding permanent magnets.

Permanent Magnet Synchronous Reluctance Motor

Permanent Magnet Synchronous Reluctance Motors are receiving much attention due to their high speed, power density and efficiency characteristics. The permanent magnets made of rare earth and neodymium have lower inertia compared with Induction Motor because of elimination of rotor cage. Hence torque to inertia ratio of PMSRM is higher. As PMSRM has negligible rotor losses, their efficiency is high. PMSRM has the excitation in the form of the rotor magnet, hence no external source of magnetizing current for excitation is required like an induction motor. Since rotor losses in PMSRM is small, the loss in the form of heat is avoided which improves the performance of the motor. PMSRM is smaller in size and has lesser weight. It is suitable for the applications where the size of machine is limited.

Top 12 Upcoming Electric Bikes In India 2021

Top 15 Upcoming Electric Scooters In India 2020 - 21

Disclaimer- some contents are used for educational purposes under fair use. Copyright disclaimer under section 107 of the Copyright Act 1976, allowance is made for "fair use" for purposes such as criticism, news reporting, teaching, scholarship, and research. Fair use is a use permitted by copyright statute that might otherwise be infringing. Non-profit, educational or personal use tips the balance in favor of fair use.

Комментарии

0:15:52

0:15:52

0:05:50

0:05:50

0:21:01

0:21:01

0:10:03

0:10:03

0:19:46

0:19:46

0:15:11

0:15:11

0:11:21

0:11:21

0:15:34

0:15:34

0:00:52

0:00:52

0:04:19

0:04:19

0:07:13

0:07:13

0:03:19

0:03:19

0:04:28

0:04:28

0:07:07

0:07:07

0:00:24

0:00:24

0:12:08

0:12:08

0:14:43

0:14:43

0:03:55

0:03:55

0:08:56

0:08:56

0:03:01

0:03:01

0:00:21

0:00:21

0:00:27

0:00:27

0:02:28

0:02:28

0:12:50

0:12:50