filmov

tv

Bambu Lab P1/X1/X1C/X1CC Filament Spool Winder if you use AMS Assembly Instruction / Final version?

Показать описание

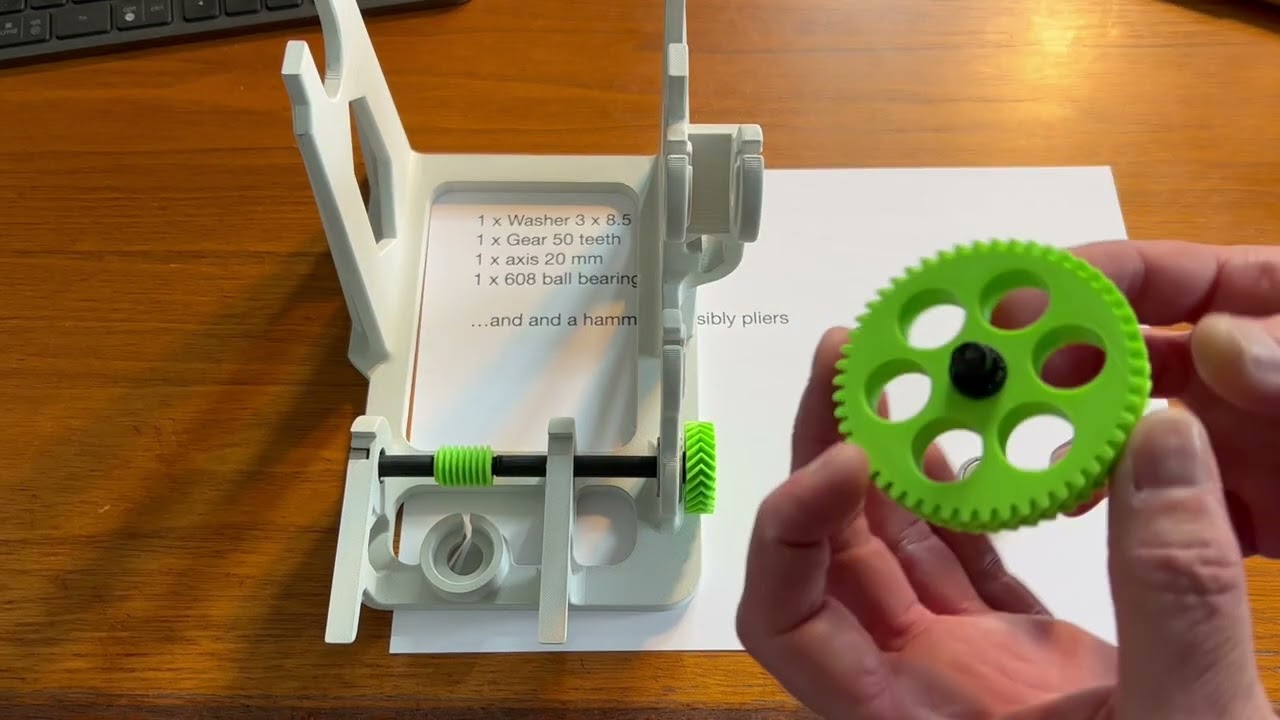

Purely mechanically controlled filament winder for Bambu Lab P1, X1, X1C or X1CC 3D Printer.

...and not, a model is never finished :)

Assembly Instruction.

00:00 Assembling the adjustment screws

00:30 Assembling the spool

01:04 Assembling the twist grip

01:49 Assembling the lower gears

04:38 Assembling the middle gear

06:00 Assembling the upper gear / drive gear

07:47 First function check - everything should run smoothly and the gears should mesh

08:07 Assembling the vertical axle for the linear drive

09:18 Assembling the filament carriage & guide

11:25 Adjusting the filament guide

...and not, a model is never finished :)

Assembly Instruction.

00:00 Assembling the adjustment screws

00:30 Assembling the spool

01:04 Assembling the twist grip

01:49 Assembling the lower gears

04:38 Assembling the middle gear

06:00 Assembling the upper gear / drive gear

07:47 First function check - everything should run smoothly and the gears should mesh

08:07 Assembling the vertical axle for the linear drive

09:18 Assembling the filament carriage & guide

11:25 Adjusting the filament guide

Bambu Lab P1/X1/X1C/X1CC Filament Spool Winder if you use AMS Assembly Instruction / Final version?

Respool Your 3D Printer Filament With Ease!

Bambu Lab Filament Spool Winder Motor Drive for Stand - Auto-Stop Function

The Bambu Lab filament spools are all refillable

Bambu Lab P1 / X1 / X1C / X1CC Filament Spool Switcher & Winder - Heavy Load Parts.

Bambu Lab P1/X1/X1C/X1CC Filament Spool Winder if you use AMS how it works...

Assemble Bambu Lab P1S/X1/X1C/X1CC/A1/P1 Filament Spool Winder

Bambu Lab P1 / X1 / X1C / X1CC Filament Spool Switcher & Winder if you use AMS

The best upgrades for your Bambu Lab 3D printer

Filament umspulen - zwei varianten ausgetestet Bambu Lab AMS relevant?

Filament Switcher & Winder | Spool Winder | Filament | Bambu Lab X1 Carbon

Bambu Lab P1 / X1 / X1C / X1CC Filament Spool Switcher & Winder Assembly Accuracy

Spool Winder Bambu Lab P1 / X1 / X1C / X1CC Filament Spool Switcher & Winder if you use AMS

Configure filament on the spool holder

Bambu Lab P1 / X1 / X1C / X1CC Filament Spool Switcher & Winder - Timelapse

Motor Power for Bambu Lab P1 / X1 / X1C / X1CC Filament Spool Switcher & Winder

respool

MY FAVORITE Bambu X1 Carbon MOD!

The 10 BEST Upgrades for your Bambu Lab 3D Printer!

Bambu Lab P1 / X1 / X1C / X1CC Filament Spool Switcher & Winder if you use AMS

Transferring filament to Bambu Lab spools

Pastamatic Filament Spool Winder in Action

Bambu Lab P1 / X1 / X1C / X1CC Filament Spool Switcher & Winder if you use AMS 3rd Video: Soluti...

Bambu Lab Must Prints: Part 3 - Reusable Spool

Комментарии

0:12:31

0:12:31

0:06:30

0:06:30

0:00:44

0:00:44

0:00:27

0:00:27

0:03:42

0:03:42

0:04:56

0:04:56

0:11:16

0:11:16

0:01:39

0:01:39

0:16:17

0:16:17

0:12:39

0:12:39

0:00:22

0:00:22

0:00:46

0:00:46

0:00:40

0:00:40

0:02:30

0:02:30

0:00:35

0:00:35

0:00:43

0:00:43

0:07:11

0:07:11

0:05:44

0:05:44

0:10:46

0:10:46

0:00:31

0:00:31

0:09:21

0:09:21

0:00:17

0:00:17

0:04:29

0:04:29

0:00:35

0:00:35