filmov

tv

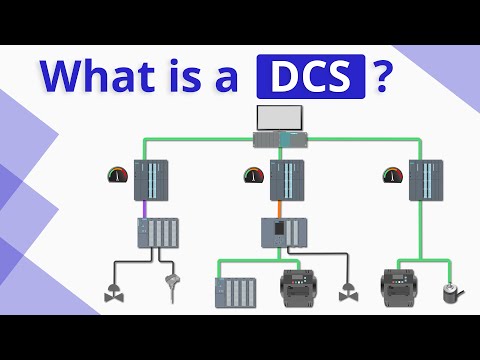

What is DCS (Distributed Control System) | DCS architecture explained

Показать описание

A distributed control system (DCS) is a computerised control system for a process or plant usually with many control loops, in which autonomous controllers are distributed throughout the system, but there is no central operator supervisory control. This is in contrast to systems that use centralized controllers; either discrete controllers located at a central control room or within a central computer. The DCS concept increases reliability and reduces installation costs by localising control functions near the process plant, with remote monitoring and supervision.

The key attribute of a DCS is its reliability due to the distribution of the control processing around nodes in the system. This mitigates a single processor failure. If a processor fails, it will only affect one section of the plant process, as opposed to a failure of a central computer which would affect the whole process. This distribution of computing power local to the field Input/Output (I/O) connection racks also ensures fast controller processing times by removing possible network and central processing delays.

The accompanying diagram is a general model which shows functional manufacturing levels using computerised control.

Referring to the diagram;

Level 0 contains the field devices such as flow and temperature sensors, and final control elements, such as control valves

Level 1 contains the industrialised Input/Output (I/O) modules, and their associated distributed electronic processors.

Level 2 contains the supervisory computers, which collect information from processor nodes on the system, and provide the operator control screens.

Level 3 is the production control level, which does not directly control the process, but is concerned with monitoring production and monitoring targets

Level 4 is the production scheduling level.

Levels 1 and 2 are the functional levels of a traditional DCS, in which all equipment are part of an integrated system from a single manufacturer.

Levels 3 and 4 are not strictly process control in the traditional sense, but where production control and scheduling takes place.

In this video, i will get the DCS architecture explained. I will take a sample ABB DCS drawing and will explain its different levels in detail.

#dcs #automation #distributedcontrolsystem

The key attribute of a DCS is its reliability due to the distribution of the control processing around nodes in the system. This mitigates a single processor failure. If a processor fails, it will only affect one section of the plant process, as opposed to a failure of a central computer which would affect the whole process. This distribution of computing power local to the field Input/Output (I/O) connection racks also ensures fast controller processing times by removing possible network and central processing delays.

The accompanying diagram is a general model which shows functional manufacturing levels using computerised control.

Referring to the diagram;

Level 0 contains the field devices such as flow and temperature sensors, and final control elements, such as control valves

Level 1 contains the industrialised Input/Output (I/O) modules, and their associated distributed electronic processors.

Level 2 contains the supervisory computers, which collect information from processor nodes on the system, and provide the operator control screens.

Level 3 is the production control level, which does not directly control the process, but is concerned with monitoring production and monitoring targets

Level 4 is the production scheduling level.

Levels 1 and 2 are the functional levels of a traditional DCS, in which all equipment are part of an integrated system from a single manufacturer.

Levels 3 and 4 are not strictly process control in the traditional sense, but where production control and scheduling takes place.

In this video, i will get the DCS architecture explained. I will take a sample ABB DCS drawing and will explain its different levels in detail.

#dcs #automation #distributedcontrolsystem

0:08:29

0:08:29

0:05:55

0:05:55

0:07:25

0:07:25

0:02:20

0:02:20

0:01:45

0:01:45

0:06:54

0:06:54

0:02:29

0:02:29

0:02:45

0:02:45

0:08:52

0:08:52

0:04:13

0:04:13

0:02:59

0:02:59

0:04:54

0:04:54

0:01:04

0:01:04

0:15:20

0:15:20

0:07:04

0:07:04

0:11:23

0:11:23

0:00:33

0:00:33

0:03:07

0:03:07

0:02:16

0:02:16

0:02:44

0:02:44

0:06:18

0:06:18

0:04:07

0:04:07

0:07:13

0:07:13

0:05:00

0:05:00