filmov

tv

How To Permanently Repair A Garage Floor Crack

Показать описание

10% Discount Code (Enter At checkout): Ehr10

I am preparing my garage floor to install an epoxy coating with the flake finish but before then I have some repair work to do. First up is permanently repairing a large crack that runs the entire length of the floor. This same fix could be done on your basement floor or your slab foundation. I am using a new fast-set epoxy for the first time and this should provide a bullet-proof fix that will stand up for decades.

Free Home Maintenance Checklist:

DISCLAIMER: This video and description contain affiliate links, which means that if you click on one of the product links, I’ll receive a small commission.

I am preparing my garage floor to install an epoxy coating with the flake finish but before then I have some repair work to do. First up is permanently repairing a large crack that runs the entire length of the floor. This same fix could be done on your basement floor or your slab foundation. I am using a new fast-set epoxy for the first time and this should provide a bullet-proof fix that will stand up for decades.

Free Home Maintenance Checklist:

DISCLAIMER: This video and description contain affiliate links, which means that if you click on one of the product links, I’ll receive a small commission.

How To PERMANENTLY Repair Cracked Plastics

What is Proper Tire Repair? See How It's Done.

Never Fear Flat Tires Again: Easy Tire Repair for Screw/Nail Punctures

Tire Sidewall PUNCTURE permanent repair procedure

How To Properly Repair a Tire

Tire Plug Puncture Repair Kit - How Does it Work ?

How to permanently secure a loose bolt or screw - Furniture Repair

How to PROPERLY Repair a Rust Hole in your Car or Truck (DIY for Beginners)

SAMSUNG S23 ULTRA SM-S918B REPAIR IMEI & LDU (LIVE DEMO UNIT) FLAG PERMANENT !!!

How To Permanently Repair Broken Plastic & Headlights with the Eastwood Hot Stapler.

Repair Your Driveway Without Wasting Money | Consumer Reports

How to Repair Cracked or Leaking Pipes Without Cutting or Threading

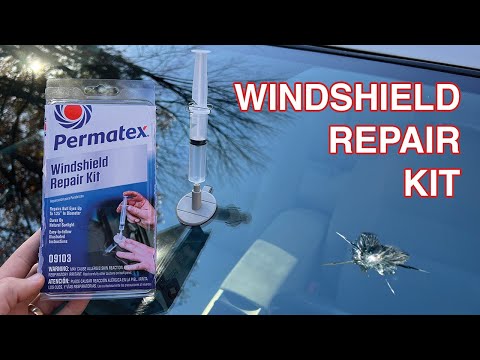

How To Fix A Windshield Crack Using Permatex Windshield Repair Kit

How to Use Universal Metal Repair Paste Repair Holes 2022

How to repair a hole in a concrete floor | Watco

How to Repair Rust on Your Car Without Welding (No Special Tools Needed)

How to Repair a Damaged Roof Vent Boot - 1 Minute Permanent Fix

Best Tire Repair Kit? SLIME, Westweld, Dynaplug, Grand Pitstop

How to Repair a Damaged Garden Hose | The Home Depot

DIY: How to repair a rust spot on a car?

How to repair a flat roof leak Underwater permanently - Karnak 19 Ultra Rubberized Flashing

How To: Repair a Leaky Sunroof

I Saved $610 - DIY - Asphalt Driveway Crack Repair

How to Repair a Cracked Bumper

Комментарии

0:13:05

0:13:05

0:01:28

0:01:28

0:05:28

0:05:28

0:19:34

0:19:34

0:10:10

0:10:10

0:03:05

0:03:05

0:01:37

0:01:37

0:34:08

0:34:08

0:15:02

0:15:02

0:13:18

0:13:18

0:01:44

0:01:44

0:02:21

0:02:21

0:08:13

0:08:13

0:00:34

0:00:34

0:03:16

0:03:16

0:21:55

0:21:55

0:02:39

0:02:39

0:14:05

0:14:05

0:01:07

0:01:07

0:03:17

0:03:17

0:03:32

0:03:32

0:02:21

0:02:21

0:06:45

0:06:45

0:19:51

0:19:51