filmov

tv

Reading Camshaft and Crankshaft signals using an Oscilloscope!

Показать описание

In this video I walk you through the actual process of retrieving a waveform. It is obvious that you need to check the cam and crank sensor.. though it is not always so obvious WHERE you are going to pull those signals from when you are a flat rate mechanic! I try to give you the tips that help me get to the reading as quickly and efficiently as possible.

I mentioned the free wiring diagram resource, if you have any requests for particular information, leave a comment below!

I mentioned the free wiring diagram resource, if you have any requests for particular information, leave a comment below!

Reading Camshaft and Crankshaft signals using an Oscilloscope!

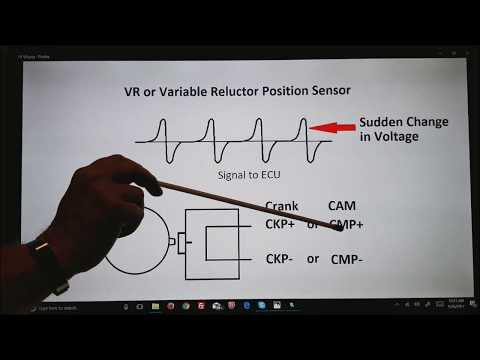

The Relationship Between Crankshaft And Camshaft Sensor Signal

Garage Gurus | Cam & Crank Correlation Waveforms

Motor Age How2 #5 - Using The CMP/CKP Signals To Check Timing

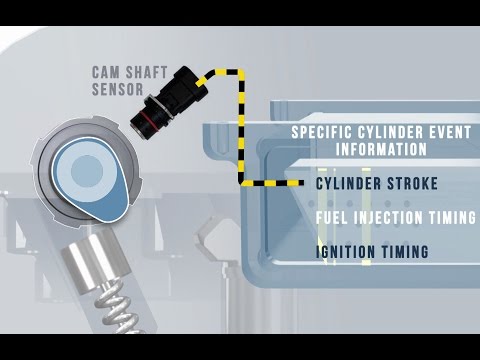

Crankshaft and Camshaft Position Sensor Signals

Live data of failing Crankshaft position sensor

Camshaft Position Sensor - Voltage High

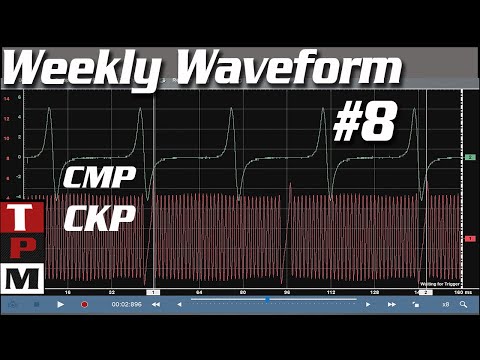

Weekly Waveform 8 - Camshaft/Crankshaft Correlation - CKP CMP

Bad Camshaft Position Sensor Symptoms - How to Test and FIX!!

Crank and Cam Sensors

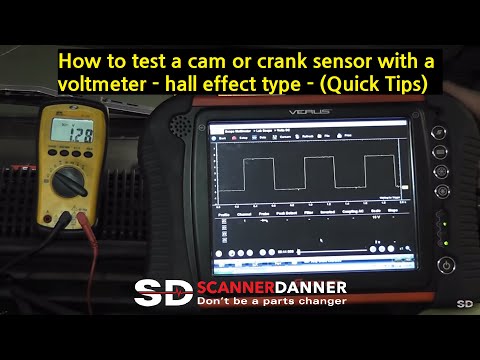

How to test a cam or crank sensor with a voltmeter - hall effect type - (Quick Tips)

HOW TO TEST CAMSHAFT POSITION SENSOR ON A CAR

How to Test Crankshaft and Camshaft Position Sensors

Testing the Cam and crank sensors

Camshaft Position Sensor - Voltage Low

How to Test & Fix P0017 Crankshaft - Camshaft Position Correlation Bank 1 Sensor B (Bank 1- Exha...

Crankshaft Camshaft Correlation Codes: P0016, P0017, P0018 and P0019

Crankshaft position sensor on scope. The little bump on the horizontal line is the evident problem.

What to Do After Replacing Crank or Camshaft Sensor and Now Engine Won't Start or Runs Rough

How to Catch an Intermittent Bad Cam or Crank Sensor

CAM and CRANK Sensor Signal Jumped Timing Detection, Automotive Oscilloscope Study Course

Scoping The Crank Sensor Signal

Crankshaft Position Sensor Test

How to Simulate CAM & CRANK Sensor Signals Using a Function Generator

Комментарии

0:12:44

0:12:44

0:01:12

0:01:12

0:14:44

0:14:44

0:12:19

0:12:19

0:03:40

0:03:40

0:01:18

0:01:18

0:01:39

0:01:39

0:14:51

0:14:51

0:08:07

0:08:07

0:10:42

0:10:42

0:09:58

0:09:58

0:05:24

0:05:24

0:07:08

0:07:08

0:02:40

0:02:40

0:01:48

0:01:48

0:13:29

0:13:29

0:02:20

0:02:20

0:00:52

0:00:52

0:03:51

0:03:51

0:12:18

0:12:18

0:10:31

0:10:31

0:10:50

0:10:50

0:04:21

0:04:21

0:04:53

0:04:53