filmov

tv

Recycling Coax Cable & Copper Wire

Показать описание

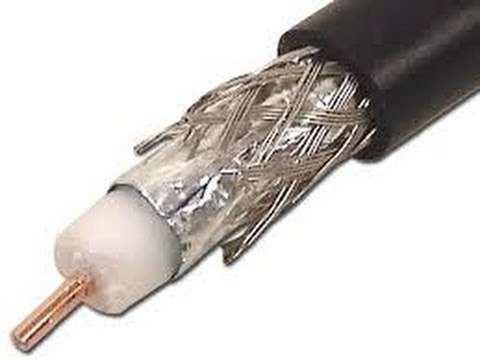

Join Jason as he demonstrates his scrap metal processing line in recycling coax cable and copper wire! In this eye-opening video, we delve into the intricate process of separating valuable materials from shredded coax cable, including copper, steel wire, and plastic.

Watch as our equipment efficiently crushes and processes the shredded coax cable, separating the copper-coated steel wire from other valuable non-magnetic components such as silver and tin-coated copper wire. Witness the precision and effectiveness of our separation techniques as we extract and recover valuable materials for recycling.

Recycling coax cable and copper wire is essential for reducing waste and conserving valuable resources. Our innovative recycling solutions are at the forefront of this effort, providing efficient and sustainable methods for recovering valuable materials from scrap metal and other electronic waste streams.

Visit our website to learn more about our scrap metal processing line and how you can implement sustainable recycling practices in your own operations. Don't forget to like, subscribe, and hit the notification bell to stay updated on our latest recycling initiatives and cutting-edge solutions!

For more info please email or call:

Phone: 360-595-4445

Keywords: Recycling Coax Cable, Copper Wire Recycling, Scrap Metal Processing, Electronic Waste Recycling, Resource Recovery, Sustainable Recycling, Recycling Solutions.

Hashtags: #CoaxCableRecycling #CopperWireRecycling #ScrapMetalProcessing #ElectronicWaste #ResourceRecovery #SustainableRecycling #RecyclingSolutions

Watch as our equipment efficiently crushes and processes the shredded coax cable, separating the copper-coated steel wire from other valuable non-magnetic components such as silver and tin-coated copper wire. Witness the precision and effectiveness of our separation techniques as we extract and recover valuable materials for recycling.

Recycling coax cable and copper wire is essential for reducing waste and conserving valuable resources. Our innovative recycling solutions are at the forefront of this effort, providing efficient and sustainable methods for recovering valuable materials from scrap metal and other electronic waste streams.

Visit our website to learn more about our scrap metal processing line and how you can implement sustainable recycling practices in your own operations. Don't forget to like, subscribe, and hit the notification bell to stay updated on our latest recycling initiatives and cutting-edge solutions!

For more info please email or call:

Phone: 360-595-4445

Keywords: Recycling Coax Cable, Copper Wire Recycling, Scrap Metal Processing, Electronic Waste Recycling, Resource Recovery, Sustainable Recycling, Recycling Solutions.

Hashtags: #CoaxCableRecycling #CopperWireRecycling #ScrapMetalProcessing #ElectronicWaste #ResourceRecovery #SustainableRecycling #RecyclingSolutions

Комментарии

0:05:09

0:05:09

0:08:11

0:08:11

0:02:28

0:02:28

0:01:06

0:01:06

0:04:00

0:04:00

0:08:50

0:08:50

0:01:55

0:01:55

0:03:01

0:03:01

0:02:14

0:02:14

0:08:43

0:08:43

0:00:31

0:00:31

0:05:56

0:05:56

0:00:30

0:00:30

0:04:31

0:04:31

0:00:38

0:00:38

0:01:00

0:01:00

0:00:49

0:00:49

0:08:37

0:08:37

0:11:36

0:11:36

0:16:14

0:16:14

0:00:33

0:00:33

0:17:04

0:17:04

0:05:46

0:05:46

0:00:47

0:00:47