filmov

tv

How To Make A LEVEL Floor System

Показать описание

This DIY exterior floor system is all about how to build a level floor system from start to finish. This floor foundation tutorial shows the step by step process of footings, beams, floor joists, sheathing installation and how to get it perfectly level. Bring Your Own Tools (#BYOTools 172).

Material List:

-5/8" Crushed Minus Rock

-4x4 PT Lumber

Tool List:

Apparel List:

MUSIC:

0:00 - Venice Beach: Topher Mohr & Alex Elena

#byot #diy #howto

Material List:

-5/8" Crushed Minus Rock

-4x4 PT Lumber

Tool List:

Apparel List:

MUSIC:

0:00 - Venice Beach: Topher Mohr & Alex Elena

#byot #diy #howto

How to make a GOOD level in GEOMETRY DASH ( GD 2.113 )

Building a Level the Way RobTop Intended It

So You Want to be a Level Designer - An Introduction to Level Design in Video Games - Extra Credits

How To Make A LEVEL Floor System

HOW to BUILD a FEATURED LEVEL in 5 MINUTES

How to Make Less Annoying Gameplay in Geometry Dash

How I Make Levels As A Professional Level Designer For Indie Games | Devlog

Creating A Level Where EVERYTHING MOVES!

10 Geometry Dash Editor Tricks to make you a FASTER Creator!

Let's Make Games: Level Design Tips

HOW TO MAKE A LEVEL! (easy) // Geometry Dash 2.1 Tutorial

How to make your lawn LEVEL and Flat - Beginners Guide to lawn levelling

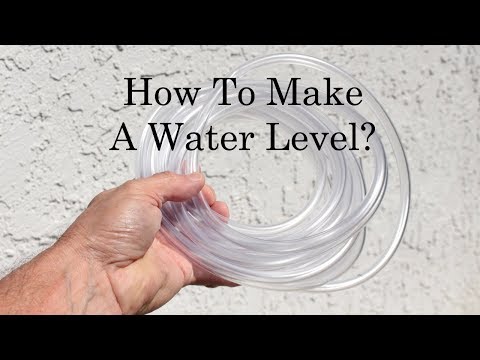

Water level basics – How to make and use one

How To Make A Water Level For Less Than Ten Dollars

How to make the perfect A level revision timetable

How I Make Levels As A Professional Level Designer // Indie Game Devlog

How To Make A FEATURE WORTHY Modern Level in GEOMETRY DASH

How to create Featured Worthy Level: Geometry Dash

Spirit level making

Building a CLASSIC level!

How to CREATE better levels in GEOMETRY DASH (2.2)

How to Make Your First Super Mario Maker 2 Level

How To Make And Use A Water Level

Building A Level At EVERY DIFFICULTY!

Комментарии

0:09:00

0:09:00

0:08:21

0:08:21

0:08:48

0:08:48

0:13:14

0:13:14

0:05:48

0:05:48

0:08:13

0:08:13

0:08:15

0:08:15

0:13:44

0:13:44

0:10:13

0:10:13

0:04:27

0:04:27

0:22:19

0:22:19

0:09:25

0:09:25

0:10:44

0:10:44

0:04:51

0:04:51

0:01:43

0:01:43

0:00:39

0:00:39

0:03:43

0:03:43

0:20:58

0:20:58

0:05:30

0:05:30

0:17:09

0:17:09

0:08:07

0:08:07

0:12:59

0:12:59

0:11:11

0:11:11

0:18:36

0:18:36