filmov

tv

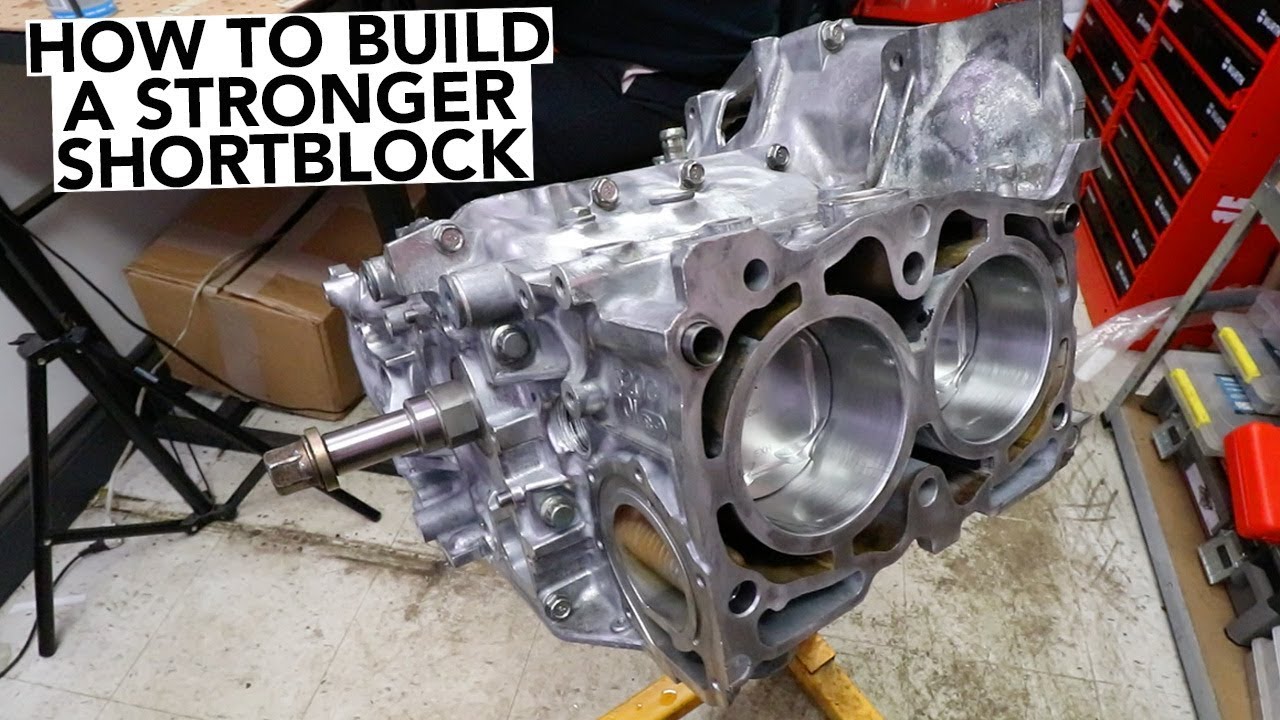

SUBARU Engine Rebuild - Short Block Assembly - Part 2

Показать описание

Our EJ20 / EJ25 Subaru engine rebuild continues with final assembly of the shortblock. This full step by step DIY installation of the pistons, rings and other parts ends with a completely assembled shortblock ready for cylinder heads.

Favorite Tools:

Favorite Tools:

SUBARU Engine Rebuild - Short Block Assembly - Part 1

SUBARU Engine Rebuild - Short Block Assembly - Part 2

Expert Guide: THE Turbo Subaru Engine Rebuild Checklist

Junkyard Subaru WRX Engine Restoration | Redline Rebuild Time-Lapse

SUBARU Engine Rebuild - Long Block Assembly - Part 2

Subaru Rebuild Checklist; What You Need To Rebuild Your Subaru

SUBARU Engine Rebuild - EJ20 / EJ25 Teardown How To

DIY Subaru Shortblock Rebuild - EJ25

Subaru Impreza WRX STI IAG Engine Rebuild #subaru

SLEEPER BUILT SUBARU // ENGINE REBUILD #shorts

Subaru Engine Rebuild #Shorts

Complete Subaru EJ25 Engine Block Rebuild/ Assembly - Many Subaru Models

Subaru Engine Rebuild, How To Know The Right Size Standard Piston

Engine Rebuild Underway! #carsofyoutube #shorts #subaru #techtips

SUBARU Engine Rebuild - Long Block Assembly - Part 1

How to Build a Subaru EJ Engine that won't BLOW UP!

SUBARU Engine Rebuild - FB20 / FB25 Step by Step Teardown and Assembly

Subaru WRX 2.5 rebuild New Pistons!!! #shorts

Subaru Engine Rebuild (EJ255) Part 1

Subaru WRX Engine Rebuild

DIY Subaru Engine Rebuild in My Garage!

The MOST in depth EJ25 rebuild tutorial EVER (wrx/sti)

Why Subaru Engines FAIL

Amazing Engine Rebuild Pistons process #short #shorts #how #mechanic #technology #repair #pistons

Комментарии

0:14:08

0:14:08

0:13:20

0:13:20

0:19:46

0:19:46

0:10:32

0:10:32

0:15:00

0:15:00

0:14:36

0:14:36

0:18:12

0:18:12

0:14:49

0:14:49

0:00:32

0:00:32

0:00:16

0:00:16

0:00:21

0:00:21

0:30:39

0:30:39

0:01:00

0:01:00

0:00:16

0:00:16

0:09:08

0:09:08

0:45:52

0:45:52

1:27:00

1:27:00

0:00:07

0:00:07

0:14:56

0:14:56

0:00:09

0:00:09

0:24:15

0:24:15

2:26:02

2:26:02

0:14:23

0:14:23

0:00:58

0:00:58