filmov

tv

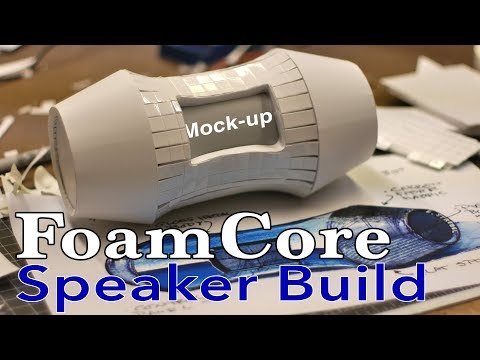

FoamCore Advanced Basics Tutorial Guide FoamBoard model making: modeling tips & tricks for Designers

Показать описание

I cover some advanced basics of how to bend cut and assemble FoamCore/ FoamBoard the right way, how not to cut the stuff and how to take things to the next level and improve your quality and craftsmanship. I make some basic 2" cylinders and soft box shapes with out exposed foam. Good for everything from architects to engineering, exhibit designers to interior designers and of course Industrial design.

My Video Gear:

PANASONIC LUMIX G X Vario Power Zoom Lens, 14-42MM Power O.I.S

Samsung 128Gb MicoSD card with adapter

Zhiyun Crane V2 3 Axis Brushless Handheld Gimbal Stabilizer

Pergear Tripod Tabletop Stand for the Zhiyun Handheld Gimbal Stabilizer

My Audio Gear:

My Hardware:

Botzen Design Inc.

Industrial Design and Product Visualization

My Video Gear:

PANASONIC LUMIX G X Vario Power Zoom Lens, 14-42MM Power O.I.S

Samsung 128Gb MicoSD card with adapter

Zhiyun Crane V2 3 Axis Brushless Handheld Gimbal Stabilizer

Pergear Tripod Tabletop Stand for the Zhiyun Handheld Gimbal Stabilizer

My Audio Gear:

My Hardware:

Botzen Design Inc.

Industrial Design and Product Visualization

FoamCore Advanced Basics Tutorial Guide FoamBoard model making: modeling tips & tricks for Desig...

FoamCore Basics Tutorial Guide FoamBoard model making: modeling tips and tricks for Designers

FoamCore Pro Tutorial Guide Foam Board model making: Compound surface modeling Techniques tips

Foam Core Trilogy: Basics, Adv. Basics & Pro Guide FoamBoard model making

Using Foamcore: Part 1

CardBoard Advanced Basics Tutorial guide for model making: modeling for Designers & Architects

FoamCore model making Design Build with Foam Board: Wireless Bluetooth Speaker Mock up and Wahey-C1

A comprehensive guide to using foamboard to make wargames terrain

How to Prepare Foam Board for Terrain Making Projects

Foamboard Buildings & Ruins - Hiding Joins

Using Foamcore: Part 3

CardBoard Basics Tutorial Guide Chip/Matte Board model making: modeling for Designers & Architec...

Terrain Tutorial: How to Create Bricks from Foamboard

Laser Model Making Advanced Basics Tutorial Guide: modeling tips & tricks for Designers Architec...

UNLOCK FoamCORE’S Inner Secret: FoamBoard EVA craft foam model making tips and tricks for Designers...

Basics: What is that foam you use and where do I get it? (Black Magic Craft Episode 028)

Guide to Prototyping in Cardboard and Foam Core!

Tips for Dollhouse Miniature Crafting- Working with Foamcore

Three more ways to add texture to watercolor paintings

Basics: How to get good, clean, straight cuts in XPS Foam (Black Magic Craft Episode 030)

Cutting and Folding 4'x8' Foam Board Into Thirds

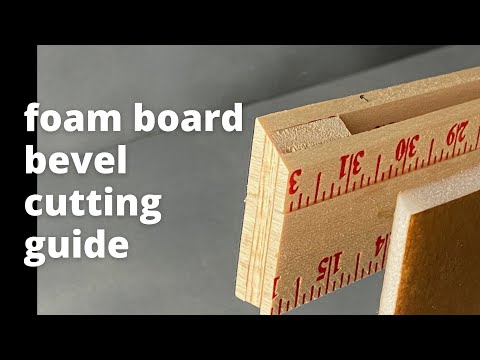

Foam Board Bevel Cutting Guide

How to Cut Foam Board

FoamWerks by Logan Animation Video Demonstration

Комментарии

0:06:41

0:06:41

0:06:19

0:06:19

0:04:09

0:04:09

0:15:57

0:15:57

0:07:25

0:07:25

0:10:58

0:10:58

0:09:00

0:09:00

0:50:34

0:50:34

0:05:14

0:05:14

0:14:13

0:14:13

0:10:03

0:10:03

0:10:10

0:10:10

0:09:10

0:09:10

0:16:15

0:16:15

0:14:30

0:14:30

0:12:10

0:12:10

0:38:38

0:38:38

0:07:29

0:07:29

0:00:35

0:00:35

0:16:57

0:16:57

0:04:58

0:04:58

0:08:05

0:08:05

0:10:19

0:10:19

0:05:15

0:05:15