filmov

tv

Kanban & Kaizen

Показать описание

What is Kanban

Kanban means many things.

Literally, Kanban is a Japanese word that means "visual card".

At Toyota, Kanban is the term used for the visual & physical signaling system that ties together the whole Lean Production system.

Kanban as used in Lean Production is over a half century old.

It is being adopted newly to some disciplines as software.

How does Kanban work?

There are many flavors, but the core of Kanban means:

Visualize the workflow

Split the work into pieces, write each item on a card and put on the wall.

Use named columns to illustrate where each item is in the workflow.

Limit WIP (work in progress) – assign explicit limits to how many items may be in progress at each workflow state.

Measure the lead time (average time to complete one item, sometimes called “cycle time”), optimize the process to make lead time as small and predictable as possible.

This is a direct implementation of a lean pull scheduling system.

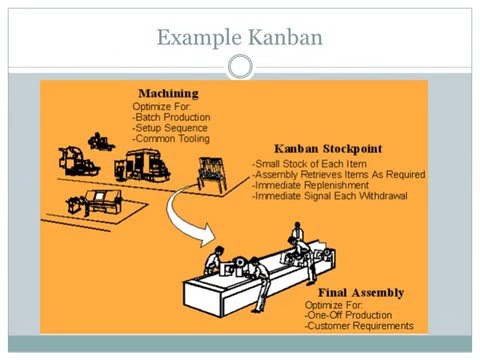

Example Kanban

Kanban

The implementation of a kanban system, as well as other lean manufacturing methods, like 5s, and kaizen, can have significant benefits for almost any type of work.

Kanban is faster, more efficient, and saves significant money over most other production models.

A kanban system is also far more directly responsive to customer demand.

Kanban is a system that visually indicates when production should start and stop.

Kanban vs. Current Process

Can I combine Kanban with my current process?

Yes. In fact, you should combine it.

In Kanban the first step is to visualize your current process, just as it is, in order to see where the bottlenecks are.

Then you introduce WIP limits and start a path of evolution that may or may not modify or replace your current process over time.

Comparison to Other Systems

What are the benefits of Kanban?

Some commonly observed benefits are:

Bottlenecks become clearly visible in real-time. This leads people to collaborate to optimize the whole value chain rather than just their part.

Useful for situations where operations and support teams have a high rate of uncertainty and variability.

Tends to naturally spread throughout the organization to other departments such as HR and sales, thereby increasing visibility of everything that is going on at the company.

Benefits of Kanban

Reduce Inventory

Kanban will reduce inventory, on average, by 25 to 75%. This saves any company significantly in terms of rent, electricity, and storage space.

In addition, all of the space freed by the implementation of a kanban system can be used for future expansions or new opportunities

Benefits of Kanban

Improve work flow

The visually organized environment ensures all parts are easily found and continually stocked.

The speed of moving from one task to another is significantly reduced by the creation of clearly marked flow lanes, kanban cards, and clearly marked labels.

Benefits of Kanban

Prevent Overproduction

Because parts are only created at the visual signal by the kanban label (link), inventory is much less likely to be overproduced. Resulting in significant savings in the holding of stock.

Benefits of Kanban

Improves responsiveness to changes in demand

Unlike a predictive system, kanban immediately reacts to the environment. By responding to clearly and easily read kanban cards the lag time between a shift in demand and a shift in production is almost non-existent.

Minimize risk of obsolete inventory, because inventory is only created as it is needed.

Common misunderstandings about Kanban

Myth: With Kanban you don’t use iterations

Fact: With Kanban iterations are optional. Do it only if you have a need for it in your context.

Myth: With Kanban you don’t estimate

Fact: With Kanban estimation is optional. Do it only if you have a need for it in your context.

Myth: Kanban is better than other tools

Fact: Kanban is just a process tool, and there is no such thing as a universally good or bad tool.

Myth: Kanban is a drop-in replacement to other tools.

Fact: Kanban is just about managing workflow. It hardly replaces anything. What it does do, however, is drive change. In Kanban you start with whatever process you have, visualize it, introduce WIP limits, and then evolve from there.

What is kaizen?

Kai is an idea of change or the action to correct — Zen means "good“

kaizen means “change for the better.

"Kaizen is the means to achieve a corporate strategy, not the strategy." - Masaaki Imai

Kaizen is a Japanese business philosophy focused on making constant improvements. Its underlying concept stresses there will always be room for improvement. Fundamentally, kaizen aims to improve all activities and processes and eliminate waste and excess.

Kanban means many things.

Literally, Kanban is a Japanese word that means "visual card".

At Toyota, Kanban is the term used for the visual & physical signaling system that ties together the whole Lean Production system.

Kanban as used in Lean Production is over a half century old.

It is being adopted newly to some disciplines as software.

How does Kanban work?

There are many flavors, but the core of Kanban means:

Visualize the workflow

Split the work into pieces, write each item on a card and put on the wall.

Use named columns to illustrate where each item is in the workflow.

Limit WIP (work in progress) – assign explicit limits to how many items may be in progress at each workflow state.

Measure the lead time (average time to complete one item, sometimes called “cycle time”), optimize the process to make lead time as small and predictable as possible.

This is a direct implementation of a lean pull scheduling system.

Example Kanban

Kanban

The implementation of a kanban system, as well as other lean manufacturing methods, like 5s, and kaizen, can have significant benefits for almost any type of work.

Kanban is faster, more efficient, and saves significant money over most other production models.

A kanban system is also far more directly responsive to customer demand.

Kanban is a system that visually indicates when production should start and stop.

Kanban vs. Current Process

Can I combine Kanban with my current process?

Yes. In fact, you should combine it.

In Kanban the first step is to visualize your current process, just as it is, in order to see where the bottlenecks are.

Then you introduce WIP limits and start a path of evolution that may or may not modify or replace your current process over time.

Comparison to Other Systems

What are the benefits of Kanban?

Some commonly observed benefits are:

Bottlenecks become clearly visible in real-time. This leads people to collaborate to optimize the whole value chain rather than just their part.

Useful for situations where operations and support teams have a high rate of uncertainty and variability.

Tends to naturally spread throughout the organization to other departments such as HR and sales, thereby increasing visibility of everything that is going on at the company.

Benefits of Kanban

Reduce Inventory

Kanban will reduce inventory, on average, by 25 to 75%. This saves any company significantly in terms of rent, electricity, and storage space.

In addition, all of the space freed by the implementation of a kanban system can be used for future expansions or new opportunities

Benefits of Kanban

Improve work flow

The visually organized environment ensures all parts are easily found and continually stocked.

The speed of moving from one task to another is significantly reduced by the creation of clearly marked flow lanes, kanban cards, and clearly marked labels.

Benefits of Kanban

Prevent Overproduction

Because parts are only created at the visual signal by the kanban label (link), inventory is much less likely to be overproduced. Resulting in significant savings in the holding of stock.

Benefits of Kanban

Improves responsiveness to changes in demand

Unlike a predictive system, kanban immediately reacts to the environment. By responding to clearly and easily read kanban cards the lag time between a shift in demand and a shift in production is almost non-existent.

Minimize risk of obsolete inventory, because inventory is only created as it is needed.

Common misunderstandings about Kanban

Myth: With Kanban you don’t use iterations

Fact: With Kanban iterations are optional. Do it only if you have a need for it in your context.

Myth: With Kanban you don’t estimate

Fact: With Kanban estimation is optional. Do it only if you have a need for it in your context.

Myth: Kanban is better than other tools

Fact: Kanban is just a process tool, and there is no such thing as a universally good or bad tool.

Myth: Kanban is a drop-in replacement to other tools.

Fact: Kanban is just about managing workflow. It hardly replaces anything. What it does do, however, is drive change. In Kanban you start with whatever process you have, visualize it, introduce WIP limits, and then evolve from there.

What is kaizen?

Kai is an idea of change or the action to correct — Zen means "good“

kaizen means “change for the better.

"Kaizen is the means to achieve a corporate strategy, not the strategy." - Masaaki Imai

Kaizen is a Japanese business philosophy focused on making constant improvements. Its underlying concept stresses there will always be room for improvement. Fundamentally, kaizen aims to improve all activities and processes and eliminate waste and excess.

Комментарии

0:03:15

0:03:15

0:03:37

0:03:37

0:02:02

0:02:02

0:02:16

0:02:16

0:02:27

0:02:27

0:18:43

0:18:43

0:04:34

0:04:34

0:02:30

0:02:30

0:46:00

0:46:00

![[Toyota Production System]](https://i.ytimg.com/vi/HIEufX83EEY/hqdefault.jpg) 0:01:14

0:01:14

0:02:35

0:02:35

0:09:09

0:09:09

0:34:54

0:34:54

0:06:09

0:06:09

0:04:11

0:04:11

0:06:32

0:06:32

0:08:44

0:08:44

0:03:21

0:03:21

0:03:12

0:03:12

0:03:46

0:03:46

0:05:18

0:05:18

0:04:43

0:04:43

0:01:49

0:01:49

0:04:00

0:04:00