filmov

tv

What is Kaizen? Kaizen and Lean Management

Показать описание

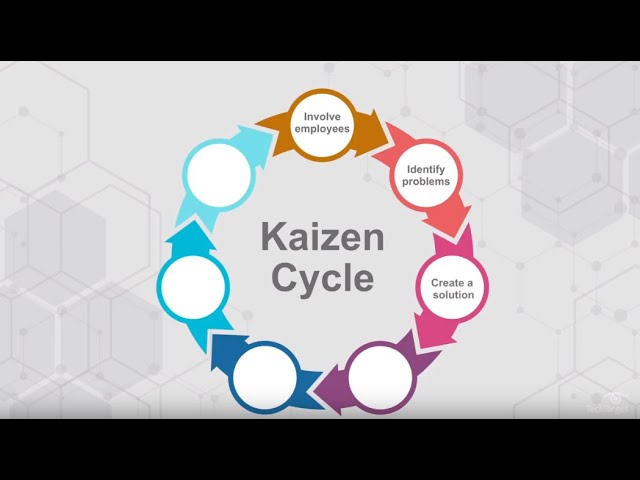

With Kaizen, think slow and steady. The little things do add up. Learn more about how Kaizen can improve business operations, and the steps of the Kaizen cycle.

🔎 Read more:

------------------------------------------------------------------------------

------------------------------------------------------------------------------

Follow Eye on Tech:

#KaizenCycle #LeanManagement #EyeOnTech

🔎 Read more:

------------------------------------------------------------------------------

------------------------------------------------------------------------------

Follow Eye on Tech:

#KaizenCycle #LeanManagement #EyeOnTech

What is Kaizen? Kaizen and Lean Management

What is Kaizen? and Continuous Improvement?

KAIZEN | A Japanese Philosophy for Continuous Improvement (PDCA Cycle)

What is Kaizen? A Continuous Improvement Culture

What is a Kaizen Event? Your Roadmap Rapid Improvement.

What is Kaizen and how can the Kaizen process be used in Lean Six Sigma manufacturing projects?

Kaizen Methodology Tutorial for Continuous Process Improvement. Kaizen Japanese Technique.

How CI, Kaizen, Lean, 6 Sigma and TPM are linked | Are CI and Kaizen the same?

Kaizen | A-Level & IB Business

Kaizen Methodology Tutorial for Continuous Process Improvement | Process Improvement using Kaizen

6 Step Kaizen Process (Plus BONUS)

What is Kaizen? Everything Your Team Needs to Know.

What is Kaizen and how it can help you

What is Kaizen | Explained in 2 min

KAIZEN Explained with Real-Life Examples - Simplest Explanation Ever

Kaizen - What is Kaizen? (Kaizen versus Kaizen Events) What is the correct approach?

What is Kaizen? - by Ritsuo Shingo former Toyota leader

A Japanese Philosophy That Will IMPROVE Your Life – Kaizen

Kaizen: The Japanese Approach to Continuous Improvement

What is 𝐊𝐀𝐈𝐙𝐄𝐍™ - Continuous Improvement in in simple language | Magical 𝑱𝒂𝒑𝒂𝒏𝒆𝒔𝒆 concept?...

What is Kaizen? | Benefits of Kaizen

Kaizen at Home - 90 Days to Success | Mike Morrill | TEDxUtica

Kaizen vs Six Sigma | Differences Between Kaizen & Six Sigma | Invensis Learning

KAIZEN, kaizen technique, kaizen in quality management, kaizen in operations management, mba, bba

Комментарии

0:02:02

0:02:02

0:07:18

0:07:18

0:04:38

0:04:38

0:04:10

0:04:10

0:01:09

0:01:09

0:02:10

0:02:10

0:12:30

0:12:30

0:22:13

0:22:13

0:02:11

0:02:11

0:34:54

0:34:54

0:09:26

0:09:26

0:01:28

0:01:28

0:00:59

0:00:59

0:02:23

0:02:23

0:14:31

0:14:31

0:01:25

0:01:25

0:06:35

0:06:35

0:05:00

0:05:00

0:01:15

0:01:15

0:10:44

0:10:44

0:02:34

0:02:34

0:13:55

0:13:55

0:28:19

0:28:19

0:08:44

0:08:44