filmov

tv

Toyota Kaizen Clip

Показать описание

Toyota Kaizen Clip

How Toyota Changed The Way We Make Things

KAIZEN | A Japanese Philosophy for Continuous Improvement (PDCA Cycle)

[Toyota Production System] Just-in-Time: The Pull System

Cheaper Better Faster: Toyota help feed Hurricane Sandy Victims

Kaizen The Secret behind Japanese Productivity

[ASSEMBLY] Commitment to Craftsmanship: The End of KAIZEN Is the Beginning of KAIZEN

Karakuri Kaizen Example from Toyota Kaikan Museum

Just in Time by Toyota: The Smartest Production System in The World

Karakuri (Low Cost Automation)

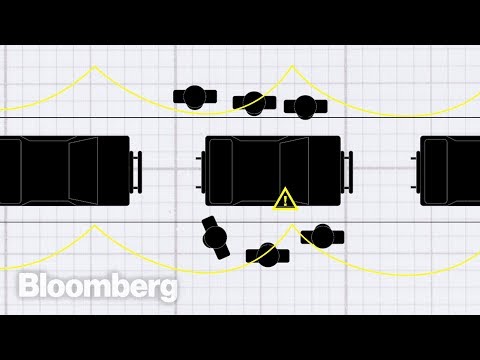

[Toyota Production System] Jidoka: Avoiding Simple Mistakes Through Poka-yoke Device

[Toyota Production System] Jidoka: Stopping Production, a Call Button and an Andon Electric Board

James May Kaizen Sketch Note

Learning from Toyota | Simon Sinek

How Toyota Changed The Way ( Kaizen)We Make Things

⚙ Lean Manufacturing | A pursuit of perfection

Toyota Material Handling | Why 5S?

Experience Kaizen Training in Japan

A DAY IN A LIFE OF A KAIZEN ENGINEER // WHAT IS DAVID DOING TODAY?

#toyota Innovation: believe in the Japanese philosophy of #kaizen

What is Kaizen? - by Ritsuo Shingo former Toyota leader

Karakuri Kaizen in Toyota

Kaizen - Toyota Service Concept Values

Why Toyota Still Makes The BEST Cars In The World - Kaizen

Комментарии

0:04:34

0:04:34

0:04:52

0:04:52

0:04:38

0:04:38

![[Toyota Production System]](https://i.ytimg.com/vi/HIEufX83EEY/hqdefault.jpg) 0:01:14

0:01:14

0:06:22

0:06:22

0:04:16

0:04:16

![[ASSEMBLY] Commitment to](https://i.ytimg.com/vi/2fMvUFs4VoE/hqdefault.jpg) 0:01:17

0:01:17

0:00:17

0:00:17

0:04:09

0:04:09

0:00:27

0:00:27

![[Toyota Production System]](https://i.ytimg.com/vi/PEfMzggk1Lw/hqdefault.jpg) 0:01:01

0:01:01

![[Toyota Production System]](https://i.ytimg.com/vi/TUKpxjAftnk/hqdefault.jpg) 0:01:43

0:01:43

0:05:19

0:05:19

0:03:04

0:03:04

0:04:52

0:04:52

0:09:14

0:09:14

0:06:19

0:06:19

0:02:50

0:02:50

0:08:09

0:08:09

0:00:42

0:00:42

0:06:35

0:06:35

0:02:10

0:02:10

0:00:48

0:00:48

0:10:52

0:10:52