filmov

tv

Assembly Line Efficiency | A day in the life at Johnson Controls

Показать описание

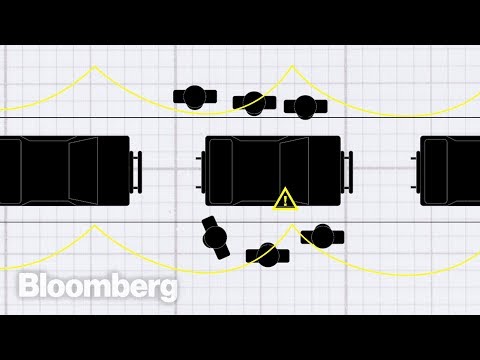

Johnson Controls Continuous Improvement Manager, Raymundo is in charge of improving responsiveness and quality, to benefit their Customers. He and his team identify roadblocks to improved efficiency and develop solutions to eliminate them. This includes everything from improving materials handling to introducing and improving automation to assembly line stations.

For more than 125 years, Johnson Controls has enjoyed tremendous global growth. Today, 168,000 employees around the world continue to enable the company's success. They create quality and innovative products, services and solutions for our customers. They seek new and better ways to improve how we work together. They make a difference in their community and for the world.

Johnson Controls employees have opportunity to learn and develop, to grow and perform to their fullest potential. They work in an environment that values their ideas, teamwork and personal safety.

Our culture expects results, and for those results to be achieved in a customer-focused, respectful manner. For delivering results, our employees are duly recognized and rewarded for their contributions.

Learn how you can join the Johnson Controls global team.

Web:

Follow us on Linkedin:

Like us on Facebook

Follow us on Twitter:

For more than 125 years, Johnson Controls has enjoyed tremendous global growth. Today, 168,000 employees around the world continue to enable the company's success. They create quality and innovative products, services and solutions for our customers. They seek new and better ways to improve how we work together. They make a difference in their community and for the world.

Johnson Controls employees have opportunity to learn and develop, to grow and perform to their fullest potential. They work in an environment that values their ideas, teamwork and personal safety.

Our culture expects results, and for those results to be achieved in a customer-focused, respectful manner. For delivering results, our employees are duly recognized and rewarded for their contributions.

Learn how you can join the Johnson Controls global team.

Web:

Follow us on Linkedin:

Like us on Facebook

Follow us on Twitter:

Комментарии

0:01:58

0:01:58

0:00:42

0:00:42

0:02:42

0:02:42

0:04:52

0:04:52

0:05:29

0:05:29

0:03:14

0:03:14

0:13:58

0:13:58

0:00:47

0:00:47

0:00:23

0:00:23

0:04:03

0:04:03

0:08:58

0:08:58

0:01:44

0:01:44

0:15:21

0:15:21

0:38:46

0:38:46

0:01:05

0:01:05

0:02:12

0:02:12

0:07:16

0:07:16

0:02:38

0:02:38

0:00:16

0:00:16

0:00:20

0:00:20

0:01:01

0:01:01

0:01:49

0:01:49

0:00:54

0:00:54

0:00:10

0:00:10