filmov

tv

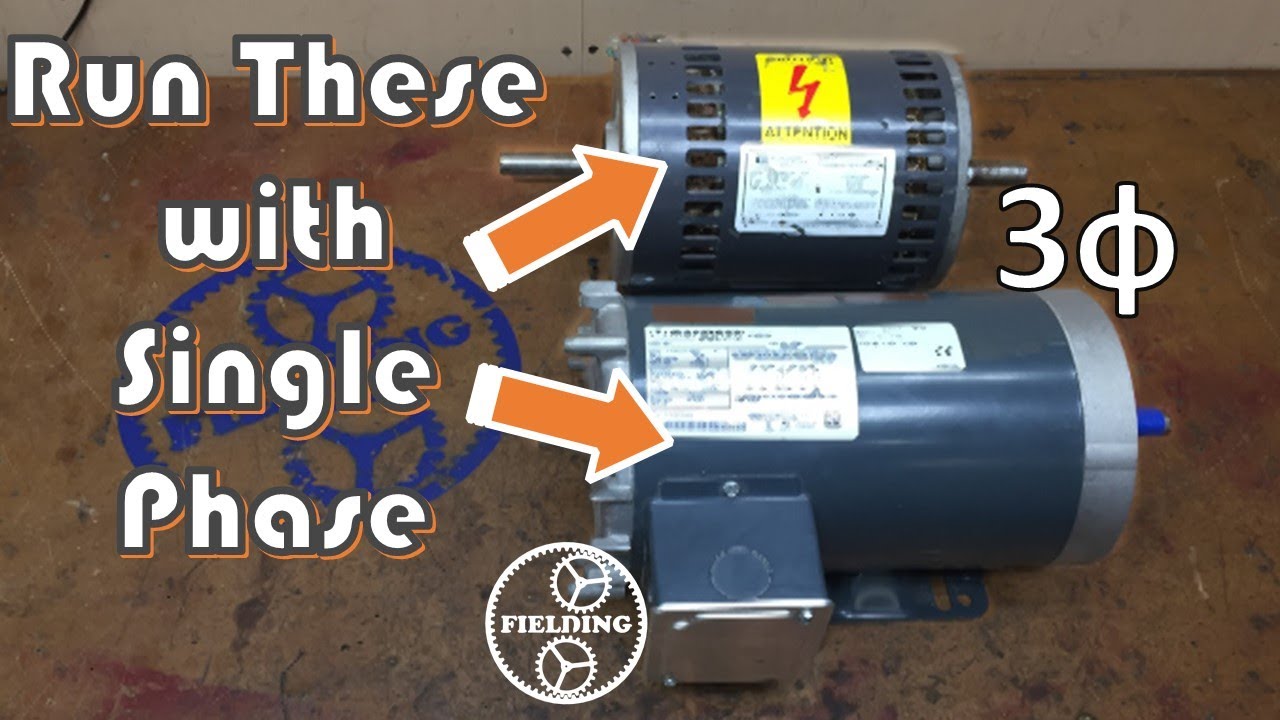

Three Ways To Run A Three Phase Motor On Single Phase, And the Pro's and Con's of Each Method #065

Показать описание

I show in detail three different methods for powering a three-phase motor with single phase power. I show all the parts, how they work together, and the pros and cons of each method. The goal is to also explain how it works, not just “put the wires here”.

If you want to chip in a few bucks to support these projects and teaching videos, please visit my Patreon page or Buy Me a Coffee.

Social media

My other channel - Fatherhood engineered

************************************

Notes:

1. Potential relays come in different ratings. So, you have to be sure you get one that matches the voltage of your motor. The one I show in the video says is is for "any potential" as long as the motor is rated for 120, or 240. Details in the link below.

2. Affiliate links to Amazon items shown in this video. Amazon gives me a small commission if you use the links below. Feel free to shop around though.

Packard Start Capacitor

Supco Potential Relay

Powerwell Run Capacitor 60 mf

Genteq Run Capacitor 35 mf

One example of a KB electronics VFD for 1 ph-3ph rated at 5.5 amps. Make sure you get one that's the right size for your application. Not necessarily this one.

Technical corrections

Nothing yet

Final Note:

PLEASE UNDERSTAND...I receive hundreds of messages on all platforms (email, Facebook, comments etc) asking for advice, and help with projects. At this volume, I simply can't do one on one advice. Thanks for your understanding on this.

If you want to chip in a few bucks to support these projects and teaching videos, please visit my Patreon page or Buy Me a Coffee.

Social media

My other channel - Fatherhood engineered

************************************

Notes:

1. Potential relays come in different ratings. So, you have to be sure you get one that matches the voltage of your motor. The one I show in the video says is is for "any potential" as long as the motor is rated for 120, or 240. Details in the link below.

2. Affiliate links to Amazon items shown in this video. Amazon gives me a small commission if you use the links below. Feel free to shop around though.

Packard Start Capacitor

Supco Potential Relay

Powerwell Run Capacitor 60 mf

Genteq Run Capacitor 35 mf

One example of a KB electronics VFD for 1 ph-3ph rated at 5.5 amps. Make sure you get one that's the right size for your application. Not necessarily this one.

Technical corrections

Nothing yet

Final Note:

PLEASE UNDERSTAND...I receive hundreds of messages on all platforms (email, Facebook, comments etc) asking for advice, and help with projects. At this volume, I simply can't do one on one advice. Thanks for your understanding on this.

Комментарии

0:22:53

0:22:53

0:07:32

0:07:32

0:08:57

0:08:57

0:07:06

0:07:06

0:05:16

0:05:16

0:11:26

0:11:26

0:10:38

0:10:38

0:13:08

0:13:08

0:00:21

0:00:21

0:21:00

0:21:00

0:02:27

0:02:27

0:00:42

0:00:42

0:07:24

0:07:24

0:12:10

0:12:10

0:01:00

0:01:00

0:13:21

0:13:21

0:08:23

0:08:23

0:08:07

0:08:07

0:14:51

0:14:51

0:06:47

0:06:47

0:06:45

0:06:45

0:15:56

0:15:56

0:12:42

0:12:42

0:11:55

0:11:55