filmov

tv

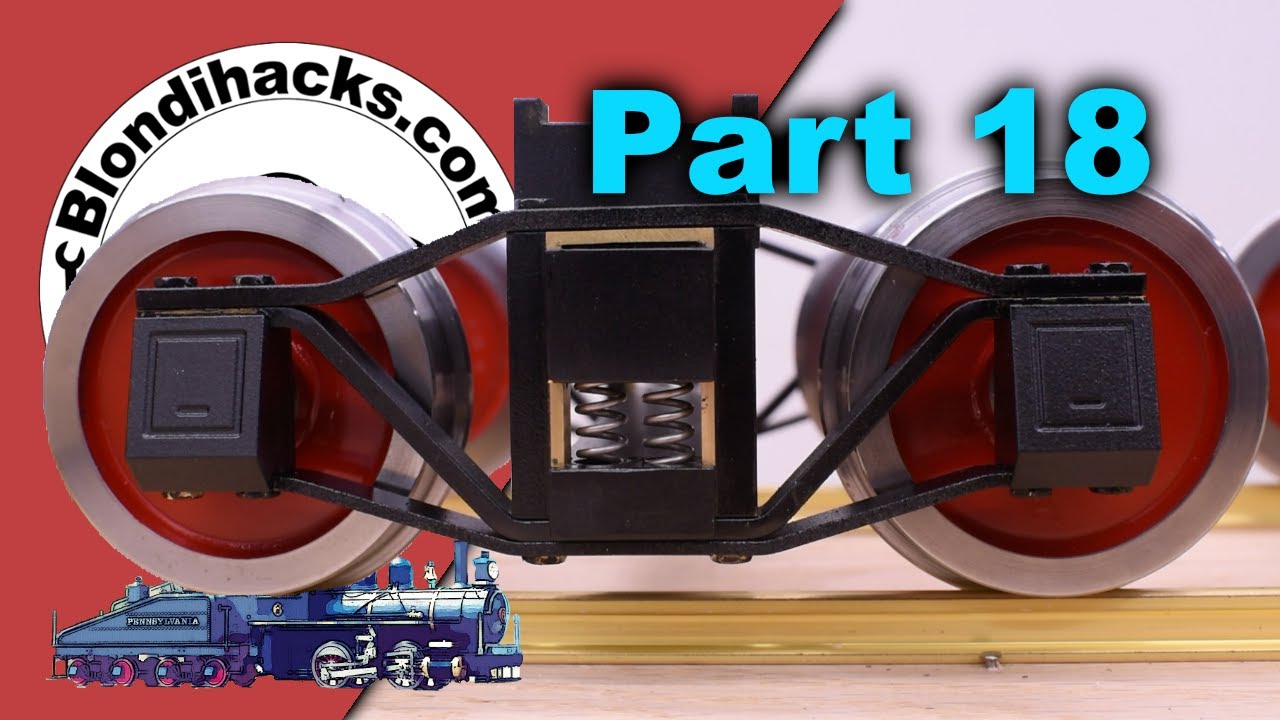

Railroad Trucks! Pennsylvania A3 Switcher, Part 18

Показать описание

This episode on Blondihacks, I’m finishing the tender trucks! Exclusive videos, drawings, models & plans available on Patreon!

Here are links for many of the tools that you see me using:

(I earn small commissions on these links)

As an Amazon Associate, I earn from qualifying purchases.

Here are links for many of the tools that you see me using:

(I earn small commissions on these links)

As an Amazon Associate, I earn from qualifying purchases.

Railroad Trucks! Pennsylvania A3 Switcher, Part 18

Building Railroad Car Suspension - Pennsylvania A3 Switcher, Part 17

Tender Water Tank - Pennsylvania A3 Switcher, Part 21

Making Train Wheels - Pennsylvania A3 Switcher, Part 15

Cylinder Heads - Pennsylvania A3 Switcher, Part 48

Finishing the Tender Chassis! Pennsylvania A3 Switcher, Part 20

TENDER IS FINISHED! - Pennsylvania A3 Switcher, Part 34

Pressure Testing The Firebox! Pennsylvania A3 Switcher, Part 10

A Big Error! Pennsylvania A3 Switcher, Part 23

November 23, 2022

Tender Frame - Pennsylvania A3 Switcher, Part 19

essai 3

Foundation Ring and Backhead! Pennsylvania A3 Switcher, Part 11

Building a Firebox! Pennsylvania A3 Switcher, Part 9

Boiler Pressure Test!!! Pennsylvania A3 Switcher, Part 13

Footboards and Gags - Pennsylvania A3 Switcher, Part 37

Adding Boiler Features - Pennsylvania A3 Switcher, Part 5

Coal Bunker! Pennsylvania A3 Switcher, Part 22

Barrel-Shaped Bearings! Pennsylvania A3 Switcher, Part 16

Finishing the Boiler!!! Pennsylvania A3 Switcher, Part 12

Boiler Outer Crown Sheet - Pennsylvania A3 Switcher, Part 8

Boiler Building Q&A! Pennsylvania A3 Switcher, Part 14

the train looks pretty weird

On30 Banta Model Works Tool Car Build Pt 3 #On30 #ModelTrain

Комментарии

0:24:54

0:24:54

0:18:15

0:18:15

0:30:03

0:30:03

0:29:54

0:29:54

0:23:09

0:23:09

0:24:28

0:24:28

0:22:48

0:22:48

0:25:56

0:25:56

0:29:05

0:29:05

0:00:13

0:00:13

0:24:49

0:24:49

0:00:48

0:00:48

0:26:31

0:26:31

0:22:20

0:22:20

0:21:21

0:21:21

0:24:22

0:24:22

0:17:54

0:17:54

0:31:16

0:31:16

0:23:42

0:23:42

0:25:19

0:25:19

0:29:48

0:29:48

0:25:33

0:25:33

0:00:12

0:00:12

0:02:42

0:02:42