filmov

tv

Tender Water Tank - Pennsylvania A3 Switcher, Part 21

Показать описание

This episode on Blondihacks, I’m working on the water tank of my A3! Exclusive videos, drawings, models & plans available on Patreon!

Here are links for many of the tools that you see me using:

(I earn small commissions on these links)

As an Amazon Associate, I earn from qualifying purchases.

Here are links for many of the tools that you see me using:

(I earn small commissions on these links)

As an Amazon Associate, I earn from qualifying purchases.

Tender Water Tank - Pennsylvania A3 Switcher, Part 21

Finishing the Tender Tank - Pennsylvania A3 Switcher, Part 24

Tender Tank Details - Pennsylvania A3 Switcher, Part 25

TENDER IS FINISHED! - Pennsylvania A3 Switcher, Part 34

How steam locomotives could refill their water tanks without stopping - The Water Scoop

Cambridge Springs, Pennsylvania, Toyne Pumper Tanker/Tender Apparatus Delivery Video

Finishing The Water Pump - Pennsylvania A3 Switcher, Part 32

Märklin 47918 - Union Pacific water tender tank cars - first published on April fool's day

Backpacking The Gerard Hiking Trail - Oil Creek State Park PA Part 1

Tanker 14 - One-Person Fill Operation at a Fire Hydrant

Bathroom plumbing installation process- Good tools and machinery make work easy

How to working fire tender centrifugal pump operation(Fire Safety)

Auxiliary Water Tender

Finishing the Tender Chassis! Pennsylvania A3 Switcher, Part 20

Trying this trend at 37 weeks pregnant #shorts

Fresh Coconut Water Making Process #shorts

DEEPEST POOL IN THE WORLD!

Ryan as a Pokemon!

Making a Water Hatch - Pennsylvania A3 Switcher, Part 26

Fire Tenders water pump test |Fire tenders testing| pump operation

Fire Engine: Rural Water Supply Response and Operations

ISSEI funny video 😂😂😂 Winter Sea #shorts

Construction technique | Brick reinforcement mesh #shorts

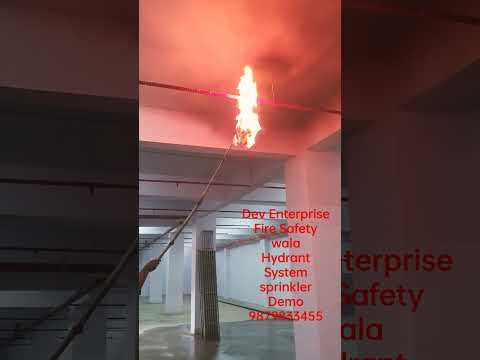

Sprinkler System Demo #hydrant #mockdrill #firesafety #fire #extinguisher #extinguisher10

Комментарии

0:30:03

0:30:03

0:31:34

0:31:34

0:24:52

0:24:52

0:22:48

0:22:48

0:03:10

0:03:10

0:02:18

0:02:18

0:26:47

0:26:47

0:01:14

0:01:14

0:18:58

0:18:58

0:06:32

0:06:32

0:00:24

0:00:24

0:05:42

0:05:42

0:06:17

0:06:17

0:24:28

0:24:28

0:00:13

0:00:13

0:00:33

0:00:33

0:00:29

0:00:29

0:00:24

0:00:24

0:27:41

0:27:41

0:03:01

0:03:01

0:17:50

0:17:50

0:00:14

0:00:14

0:00:18

0:00:18

0:00:21

0:00:21