filmov

tv

How To Braze Copper Pipe Like A Pro (HVAC Refrigerant Lines)

Показать описание

Step by step tutorial on how to braze copper pipe like a pro! We will be brazing or silver soldering refrigerant A/C lines for HVAC equipment! Thank for you watching & enjoy

TurboTorch Kit X-4B (A/C & Refrigeration kit)

Diversitech Heat Resistant Cloth 18x18 (Flame Barrier Drop Cloth Up To 3,000 Degrees F.)

Spark Lighter W/5 Extra Flints For Lighting Torch

Deburring Tool (Aluminum, Copper, Brass & Plastic)

4 in 1 Plumbers Brush (Copper Pipe Sanding Brush)

Emery Cloth (Roll of Sandpaper)

Rigid Tubing Cutter (1/8"-5/8")

Rigid Tubing Cutter (1/4"- 1 1/8")

Rigid Tubing Cutter (1/4"- 1 3/8")

Rigid Tubing Cutter (1/4"- 1 7/8")

Rigid Tubing Cutter (1/4"- 2 5/8")

► Music Credit: Dj Quads

Track Name: "www is a thing"

TurboTorch Kit X-4B (A/C & Refrigeration kit)

Diversitech Heat Resistant Cloth 18x18 (Flame Barrier Drop Cloth Up To 3,000 Degrees F.)

Spark Lighter W/5 Extra Flints For Lighting Torch

Deburring Tool (Aluminum, Copper, Brass & Plastic)

4 in 1 Plumbers Brush (Copper Pipe Sanding Brush)

Emery Cloth (Roll of Sandpaper)

Rigid Tubing Cutter (1/8"-5/8")

Rigid Tubing Cutter (1/4"- 1 1/8")

Rigid Tubing Cutter (1/4"- 1 3/8")

Rigid Tubing Cutter (1/4"- 1 7/8")

Rigid Tubing Cutter (1/4"- 2 5/8")

► Music Credit: Dj Quads

Track Name: "www is a thing"

How Professional Plumbers BRAZE COPPER LINES

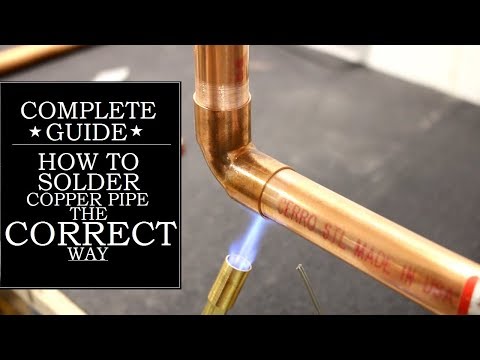

How to Solder Copper Pipe The CORRECT Way | GOT2LEARN

How To Braze Copper Pipe Like A Pro (HVAC Refrigerant Lines)

How To Silver Solder (Braze) a Copper Pipe (A/C Line Repair) | GOT2LEARN

How To Solder Copper Pipe Like a Pro (Tips & Tricks) | GOT2LEARN

The BEST Way to Braze Copper Pipes

How To Braze Copper Pipe Plumbing in Air Conditioning Unit

Brazing copper

Brazing copper

Copper Pipe Brazing for AC | #HVAC #CopperBrazing #RoofWork #AirConditioner #Installation #acinstall

How To Solder Copper Pipe (Complete Guide) Plumbing 101

How to Braze Copper Plumbing Lines

How to BRAZE Copper Plumbing Lines

Solder Vertical Copper Pipes for Beginners

How to Solder a Pipe | Ask Richard | Ask This Old House

Soldering 1-1/2' Copper Pipe #shorts

Brazing copper pipe #brazing #refrigerator #hvac

How To Braze AC Copper Lines With Nitrogen

Oxy Acetylene Brazing, Torch Adjustments- Reducing Flame, Oxidizing Flame, Neutral Flame

How To Solder Copper Pipes Like A Pro

HOW TO SOLDER COPPER PIPE | Real World Plumbing #howto #plumbing #asmr

Soldering Copper Pro Press Fittings, REALLY?🤔#plumbing

Brazing copper pipe 22mm for mapp torch

How To Solder Copper Pipes Like A Pro #diy #shorts

Комментарии

0:14:37

0:14:37

0:05:05

0:05:05

0:06:43

0:06:43

0:10:07

0:10:07

0:10:46

0:10:46

0:09:08

0:09:08

0:00:11

0:00:11

0:00:37

0:00:37

0:00:30

0:00:30

0:00:40

0:00:40

0:05:54

0:05:54

0:00:29

0:00:29

0:08:43

0:08:43

0:03:22

0:03:22

0:01:53

0:01:53

0:00:20

0:00:20

0:00:33

0:00:33

0:08:57

0:08:57

0:06:16

0:06:16

0:11:56

0:11:56

0:00:34

0:00:34

0:00:39

0:00:39

0:01:20

0:01:20

0:00:20

0:00:20