filmov

tv

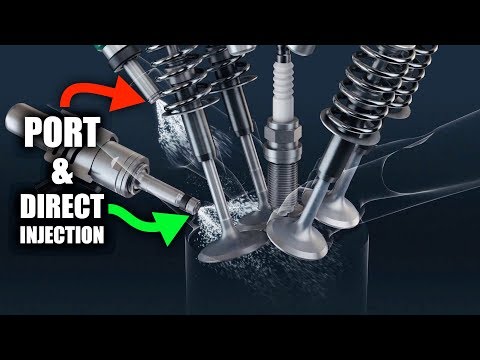

Direct vs Port Injection System

Показать описание

Direct injection (DI) and port fuel injection (PFI) are two common fuel injection systems used in internal combustion engines. Here's a brief comparison of the two:

Port Fuel Injection (PFI):

Location of Injection:

Fuel is injected into the intake port, upstream of the intake valve.

The fuel mixes with the incoming air before entering the combustion chamber.

Fuel Atomization:

Fuel atomization tends to be less fine compared to direct injection.

The fuel has more time to mix with air in the intake port, leading to better air-fuel mixing.

Combustion Characteristics:

Generally results in a more homogeneous air-fuel mixture.

Can contribute to lower peak combustion temperatures.

Carbon Deposits:

Because fuel is injected before the intake valve, it can help keep the intake valves cleaner by washing them with fuel.

Performance:

Traditionally used in many older engine designs.

May be simpler and less expensive to implement.

Direct Injection (DI):

Location of Injection:

Fuel is directly injected into the combustion chamber, usually just before or during the compression stroke.

Allows for precise control of the fuel delivery.

Fuel Atomization:

Enables finer fuel atomization due to high-pressure injection directly into the combustion chamber.

Results in better mixing with air and more efficient combustion.

Combustion Characteristics:

Can result in stratified charge combustion, where different regions of the combustion chamber have different air-fuel ratios.

Allows for more control over combustion timing and can contribute to higher efficiency.

Carbon Deposits:

Direct injection can lead to carbon deposits on the back of intake valves since fuel doesn't wash over them during the intake stroke.

Performance:

Often associated with improved power and fuel efficiency.

Common in modern engine designs, especially in turbocharged and high-performance applications.

Summary:

PFI Advantages:

Simplicity.

Generally cleaner intake valves.

Cost-effectiveness.

DI Advantages:

Improved fuel efficiency.

Better control over combustion.

Higher power output potential.

The choice between port fuel injection and direct injection depends on various factors, including the engine's design goals, performance requirements, and efficiency targets. Many modern engines use a combination of both (known as GDI or Gasoline Direct Injection) to take advantage of the strengths of each system in different operating conditions

Port Fuel Injection (PFI):

Location of Injection:

Fuel is injected into the intake port, upstream of the intake valve.

The fuel mixes with the incoming air before entering the combustion chamber.

Fuel Atomization:

Fuel atomization tends to be less fine compared to direct injection.

The fuel has more time to mix with air in the intake port, leading to better air-fuel mixing.

Combustion Characteristics:

Generally results in a more homogeneous air-fuel mixture.

Can contribute to lower peak combustion temperatures.

Carbon Deposits:

Because fuel is injected before the intake valve, it can help keep the intake valves cleaner by washing them with fuel.

Performance:

Traditionally used in many older engine designs.

May be simpler and less expensive to implement.

Direct Injection (DI):

Location of Injection:

Fuel is directly injected into the combustion chamber, usually just before or during the compression stroke.

Allows for precise control of the fuel delivery.

Fuel Atomization:

Enables finer fuel atomization due to high-pressure injection directly into the combustion chamber.

Results in better mixing with air and more efficient combustion.

Combustion Characteristics:

Can result in stratified charge combustion, where different regions of the combustion chamber have different air-fuel ratios.

Allows for more control over combustion timing and can contribute to higher efficiency.

Carbon Deposits:

Direct injection can lead to carbon deposits on the back of intake valves since fuel doesn't wash over them during the intake stroke.

Performance:

Often associated with improved power and fuel efficiency.

Common in modern engine designs, especially in turbocharged and high-performance applications.

Summary:

PFI Advantages:

Simplicity.

Generally cleaner intake valves.

Cost-effectiveness.

DI Advantages:

Improved fuel efficiency.

Better control over combustion.

Higher power output potential.

The choice between port fuel injection and direct injection depends on various factors, including the engine's design goals, performance requirements, and efficiency targets. Many modern engines use a combination of both (known as GDI or Gasoline Direct Injection) to take advantage of the strengths of each system in different operating conditions

Комментарии

0:21:47

0:21:47

0:11:41

0:11:41

0:08:51

0:08:51

0:12:07

0:12:07

0:10:21

0:10:21

0:02:37

0:02:37

0:22:14

0:22:14

0:04:23

0:04:23

0:14:40

0:14:40

0:00:50

0:00:50

0:02:54

0:02:54

0:22:08

0:22:08

0:06:27

0:06:27

0:01:23

0:01:23

0:02:26

0:02:26

0:01:00

0:01:00

0:10:26

0:10:26

0:00:08

0:00:08

0:00:07

0:00:07

0:00:28

0:00:28

0:05:54

0:05:54

0:09:34

0:09:34

0:08:31

0:08:31

0:03:06

0:03:06