filmov

tv

Why Racers Can't Let Go Of These 'Outdated' Wheels

Показать описание

A decade after Gwin’s infamous run, many of the top riders are still using DT Swiss EX471. The alloy rim, which uses a 25mm inner width, is a hit for so many reasons, not least its mixture of durability and compliance. Speaking to Troy’s mechanic, Aaron, and he explains that the narrower profile can also give a rounder profile to the tyre, which is preferential for some. He’s not the only one either. Notably, the Specialized Gravity team often opt for the classic rim, too. Henry also catches up with Specialized Gravity Racing, Neko Mullaly and discusses SR Suntours new Damper

Get unlimited access to all the best mountain biking trails by clicking the link above.

Subscribe for more content from the pulse of mountain biking.

Get unlimited access to all the best mountain biking trails by clicking the link above.

Subscribe for more content from the pulse of mountain biking.

How To Stop Racing Thoughts (Life Changing)

Racing Thoughts While Trying To Sleep? Try This.

Robbie Dolan Sings 'Let It Go' | The Blind Auditions | The Voice Australia

CHEAP $50 RACING SIMULATOR?

Are racing wheels ACTUALLY cool? 🎮

CEO Hate Ugly Wife&Flirts With Mistress! But When She Dumps Him And Shows Up Stunningly, He Regr...

How F1 racers turn really fast

Intrusive Thoughts and Overthinking: The Skill of Cognitive Defusion 20/30

Stop Your Mind from Racing at Night | Insomnia

Handling Rumination/Thought Spirals: Tips on How to Cope With Self-Destructive Thoughts

Stress is KILLING You | This is WHY and What You Can Do | Dr. Joe Dispenza (Eye Opening Speech)

Caillou Has The Fire Truck Rap #shorts

James Takes Over McLaren Racing at Miami Grand Prix

If it wasn’t for Moza Racing and Next Level Racing the sim would not be near what it is today!!

Scary TEETH-Brush!! #Shorts

Jannie and Charlotte Learn to Play Nice Together and Compete in Black vs Pink Colors Challenge!

Yung Bleu - You're Mines Still (feat. Drake) [Official Video]

Sleep, Anxiety, and Insomnia: How to Sleep Better When You're Anxious

How Fast is the NEW ICEBORN CAR in Roblox Jailbreak?

Racer flips over the gate after someone imitates the start. Who’s liable? Attorney Ugo Lord reacts!...

Abandoned Race Cars😪 #shorts #abandoned #Rally #wrc #cars #youtubeshort #racing #rallycar #nostalgia...

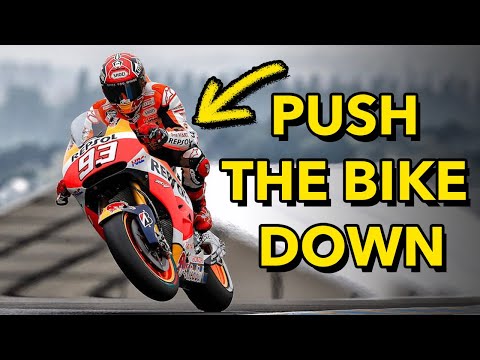

10 Things MotoGP Racers do to go FASTER

How to LEARN Car Handling in Sim Racing!

How to Make MILLIONS with a STOCK Car! - No Limit Drag Racing 2.0 Money Guide

Комментарии

0:23:52

0:23:52

0:10:15

0:10:15

0:02:25

0:02:25

0:00:30

0:00:30

0:00:20

0:00:20

2:04:10

2:04:10

0:06:29

0:06:29

0:20:04

0:20:04

0:01:20

0:01:20

0:13:05

0:13:05

0:13:03

0:13:03

0:00:32

0:00:32

0:13:25

0:13:25

0:00:52

0:00:52

0:00:43

0:00:43

0:05:10

0:05:10

0:04:18

0:04:18

0:14:07

0:14:07

0:00:34

0:00:34

0:00:58

0:00:58

0:00:16

0:00:16

0:09:22

0:09:22

0:01:00

0:01:00

0:05:29

0:05:29