filmov

tv

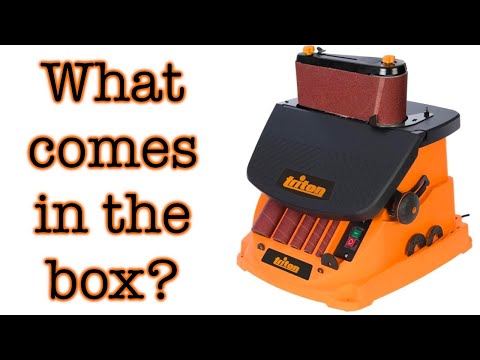

Triton Oscillating Spindle & Belt Sander Re-Review After 2 Years of Use

Показать описание

Triton Oscillating Spindle & Belt Sander Re-Review After 2 Years of Use

In this video I will be going through my thoughts on my Triton oscillating spindle and belt sander after two years of use. See the video to find out what I think about this machine, if anything went wrong with it, any issues I have found etc.

All my tools, woodworking accessories and video making kit is now in one place for you to check out. These are Amazon affiliate links. With a purchase through this link, you get an awesome tool and you will support my channel without spending a penny more.

Link to Amazon is just below! Thanks!

Tools I use and recommend:

You can now support my channel via Patreon. If you feel my content adds value for you or its entertaining then help me continue to do so.

You can support my channel by dropping some change in the Casual DIY Tip Box. Thanks for your support!

You can find me on:

#casualdiy #woodworking #tritonsander

In this video I will be going through my thoughts on my Triton oscillating spindle and belt sander after two years of use. See the video to find out what I think about this machine, if anything went wrong with it, any issues I have found etc.

All my tools, woodworking accessories and video making kit is now in one place for you to check out. These are Amazon affiliate links. With a purchase through this link, you get an awesome tool and you will support my channel without spending a penny more.

Link to Amazon is just below! Thanks!

Tools I use and recommend:

You can now support my channel via Patreon. If you feel my content adds value for you or its entertaining then help me continue to do so.

You can support my channel by dropping some change in the Casual DIY Tip Box. Thanks for your support!

You can find me on:

#casualdiy #woodworking #tritonsander

Triton TSPS450 or TSPST450 Oscillating Spindle Sanders – Which Should You Buy?

Triton Oscillating Spindle & Belt Sander - Review and demonstration. A great bit of kit!

Triton Oscillating Spindle & Belt Sander Re-Review After 2 Years of Use

Unboxing the Triton TSPST450 Spindle & Belt Sander || Aussie Tool Reviews

TRITON SPINDLE-BELT SANDER Test for sanding squareness

Problems with Triton Spindle and Belt Sander... Again

Triton Oscillating Spindle & Belt Sander, First Impressions, setup and first use

TRITON 450W oscillating spindle & belt sander

7. Triton Oscillating Spindle/Bobin Sander Review (TSPS450)

the small shed #85 - Triton TSPST 450 Belt and Spindle sander review

Triton TSPST450 OSCILLATING SPINDLE & BELT SANDER Unboxing

#80 Triton 450W Oscillating Spindle & Belt Sander Review

Triton oscillating spindle & belt sander unboxing and review

Unboxing the Triton Oscillating Spindle and Belt Sander TSPST 450 - [0087]

Triton TSPST450 450W Oscillating Spindle & Belt Sander - unboxing and review

New Tool Day Triton 450w oscillating spindle sander

Triton Spindle and Belt Sander Broke Down on Me - Plus Solution How to Fix It

The GAME CHANGING Woodworking Tool Few People Regret Buying!

Triton TSPST450 3.5A Oscillating Spindle and Belt Sander Unbox, Assemble, review

THE NEW TRITON 3.5A OSCILLATING SPINDLE AND BELT SANDER

Opening my new Triton Oscillating Spindle sander - Hyperlapse

Do you need a spindle sander?

✅ Best Oscillating Belt And Spindle Sander In 2023 ✨ Top 5 Tested & Buying Guide

Triton Spindle Belt Sander - First Look

Комментарии

0:03:33

0:03:33

0:09:57

0:09:57

0:12:41

0:12:41

0:03:49

0:03:49

0:00:49

0:00:49

0:07:44

0:07:44

0:05:38

0:05:38

0:01:26

0:01:26

0:09:57

0:09:57

0:16:49

0:16:49

0:09:25

0:09:25

0:12:01

0:12:01

0:13:44

0:13:44

0:09:13

0:09:13

0:18:29

0:18:29

0:08:23

0:08:23

0:06:38

0:06:38

0:08:06

0:08:06

0:12:22

0:12:22

0:10:55

0:10:55

0:04:26

0:04:26

0:03:59

0:03:59

0:05:44

0:05:44

0:04:22

0:04:22