filmov

tv

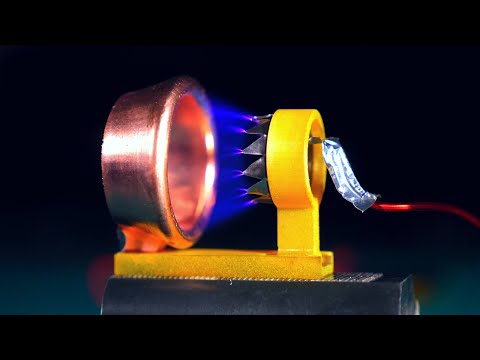

Metal Plated Ceramic Rocket Engine (3D Printed)

Показать описание

3D Models

Music

attitude---instrumental-version by wearethegood Artlist

boogie-down-bordeaux by bob-hart Artlist

maculelê---instrumental-version by maitê-inaê Artlist

TheDude by AnthonyVega Artlist

SkatePark by AlonPeretz Artlist

big---instrumental-version by wearethegood Artlist

this-blue-moon---instrumental-version by ian-post Artlist

march-of-toys by anbr Artlist

easy-as-pie by benjamin-esterlis Artlist

TheFunnyNeighbor by AnthonyVega Artlist

Boom by WEARETHEGOOD Artlist

dont-be-stupid by anthony-vega Artlist

maple-leaf-rag-joplin by raphaël-angelini Artlist

gypsy-bill---instrumental-version by ofer-koren Artlist

a-scary-ferris-wheel-ride by ziv-grinberg Artlist

smile-in-advance by hanjo-gabler Artlist

midnight-escape---theremin-pads--bells by ziv-moran Artlist

run by anbr Artlist

breaking-of-glass by iby Artlist

gypsy-bill---instrumental-version by ofer-koren Artlist

OpenHorizons by AnthonyVega Artlist

summertime---instrumental-version by sandy-pierce Artlist

#rocket #engine #3dprinting

Metal Plated Ceramic Rocket Engine (3D Printed)

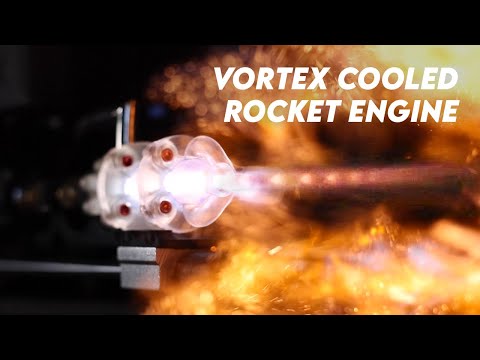

Vortex Cooled Ceramic Rocket Engine (3D Printed)

The Idea Was Simple... A Ceramic Vortex Rocket!

NASA's clever technique to make combustion chambers

I 3D printed a CO2 Rocket

The Forgotten Nazi Cold Rocket Engine (3D Printed)

GLASS ROCKET ENGINE

Aerospike Hybrid Rocket Engine (3D printed)

How Transparent Aluminum Could Make Star Trek Technology a Reality

Building a Liquid rocket engine! - I built a bipropellant rocket engine as a student engineer!

3D Printed Vortex Rocket Engine Igniter

bullet proof suit 😱

World’s Most Complex 3D Printed Part is made from Titanium

I built a Metal 3D Printer using my Welding Machine

VAPING GAVE US CANCER #stopvaping

Making ROCKET Engine Fuel Injectors - FINAL STEPS!

PULSED DETONATION ENGINE

Carbon Fiber Jet Engine

I 3D Printed a Transparent Combustion Engine in Resin

Making Shock Diamonds with a 3D Printed Rocket Nozzle

I built an IONIC PLASMA THRUSTER (Best Design)

I turned my DYSON HAIRDRYER into a JET ENGINE

Devil's Toothpaste Rocket Engine (3D Printed)

Can You Throttle a Solid Rocket Motor?

Комментарии

0:21:14

0:21:14

0:17:00

0:17:00

0:01:00

0:01:00

0:16:19

0:16:19

0:08:44

0:08:44

0:14:32

0:14:32

0:15:20

0:15:20

0:19:30

0:19:30

0:04:32

0:04:32

0:21:03

0:21:03

0:05:14

0:05:14

0:00:16

0:00:16

0:04:49

0:04:49

0:12:15

0:12:15

0:00:11

0:00:11

0:09:26

0:09:26

0:12:38

0:12:38

0:13:32

0:13:32

0:11:31

0:11:31

0:14:35

0:14:35

0:09:11

0:09:11

0:10:34

0:10:34

0:18:31

0:18:31

0:16:22

0:16:22