filmov

tv

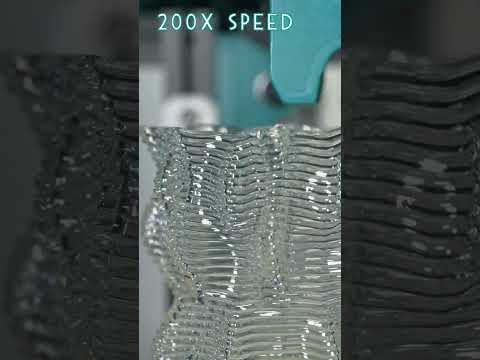

I 3D Printed a Transparent Combustion Engine in Resin

Показать описание

3D Models

Videos

#transparent #engine #3dprinting

Transparent 3D Printing!

Can We Make 3D Printed Clear Resin Look as Transparent as Glass?

I 3D Printed a Transparent Combustion Engine in Resin

Clearest Clear Resin for 3D Printing?

Transparent FDM 3D Prints are Clearly Stronger!

YOUSU 3D printing High transparent resin shell

What do you think? Transparent, Translucent, or Black 3D Printing Filament?

How to make 3d printed parts transparent like glass

Part1 articulating hippo in tinkercad for 3d printing

😮 Transparent PLA - Some 3D Printing Tests

Elegoo Neptune 3 Plus printing transparent filament 3D printing farm in Bangladesh

How to create transparent 3D prints!

Transparent 3D Printing with New PETG Material

Optically transparent 3D prints with Taulman3D's T-Glase! #Filaween

Transparent 3D Printing

Anycubic High Clear Resin | Resist Yellowing-Highly Transparent-Tough and Resilient

Dehydrating Clear PLA Filament

My 3D Printed Transparent SNES Controller is a Clear Upgrade!

3d printed resin looking transparent like glass 😎 #3dprinting #miniature #dnd #minipainting

High toughness transparent 3D printed sla resin from Magforms

Bambu Lab X1 transparent test - Finally the 3D printer customers want?

3D-Druck mit Nobufil PETG Transparent / 3D Printing with Nobufil PETG Transparent

Blue Transparent Resin Oni Mask #3 STL available on Kawaiiwong.com @ANYCUBIC3D photo. mono x2

Transparent resin 3D printing model for confirmation before customizing bottle production molds

Комментарии

0:04:16

0:04:16

0:01:20

0:01:20

0:11:31

0:11:31

0:00:59

0:00:59

0:18:03

0:18:03

0:00:22

0:00:22

0:00:27

0:00:27

0:02:21

0:02:21

0:19:47

0:19:47

0:01:00

0:01:00

0:00:05

0:00:05

0:12:56

0:12:56

0:01:45

0:01:45

0:01:30

0:01:30

0:00:17

0:00:17

0:00:54

0:00:54

0:00:39

0:00:39

0:13:13

0:13:13

0:00:59

0:00:59

0:01:05

0:01:05

0:22:42

0:22:42

0:01:00

0:01:00

0:00:59

0:00:59

0:00:14

0:00:14