filmov

tv

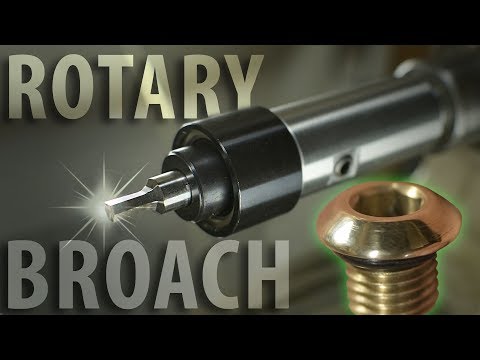

Making A Rotary Broach - Cutting Hex Sided Holes (DIY)

Показать описание

G'day everyone,

In this video I will be showing you the journey that I undertook to try and cut my own hex sockets. To do this I need to make use of a rotary broaching tool. There are commercial versions of this tool, but they are out of my price range for a hobby shop, so I decided to make my own. This will be a rotary broach tool for the lathe.

Making one should be a pretty straight forward job, but there are fine details that need to be done correctly in order to do this correctly. It took me a few weeks and several revisions to make this work. I hope you enjoy this video.

The two links below are well worth checking out. They provided me with a useful direction to go in when designing this tool.

Timestamps

0:00 - Intro

1:06 - Making The Tool Housing

2:34 - Machining The Housing

3:48 - Machining The Shaft

5:06 - Machining A Backstop

6:21 - Finishing The Housing

7:16 - Cutting The Dovetails

8:02 - First Assembly

8:45 - Making The Broach Cutters

10:17 - Adding The Ball Bearings

10:48 - First Test Cuts

12:00 - Making A HSS Cutter

12:54 - Using The Rotary Broach

#DIY #Machining #RotaryBroach

Mill - Sieg X2.7l

Lathe Sieg c3 7x14 Mini Metal Lathe

In this video I will be showing you the journey that I undertook to try and cut my own hex sockets. To do this I need to make use of a rotary broaching tool. There are commercial versions of this tool, but they are out of my price range for a hobby shop, so I decided to make my own. This will be a rotary broach tool for the lathe.

Making one should be a pretty straight forward job, but there are fine details that need to be done correctly in order to do this correctly. It took me a few weeks and several revisions to make this work. I hope you enjoy this video.

The two links below are well worth checking out. They provided me with a useful direction to go in when designing this tool.

Timestamps

0:00 - Intro

1:06 - Making The Tool Housing

2:34 - Machining The Housing

3:48 - Machining The Shaft

5:06 - Machining A Backstop

6:21 - Finishing The Housing

7:16 - Cutting The Dovetails

8:02 - First Assembly

8:45 - Making The Broach Cutters

10:17 - Adding The Ball Bearings

10:48 - First Test Cuts

12:00 - Making A HSS Cutter

12:54 - Using The Rotary Broach

#DIY #Machining #RotaryBroach

Mill - Sieg X2.7l

Lathe Sieg c3 7x14 Mini Metal Lathe

Комментарии

0:12:39

0:12:39

0:14:18

0:14:18

0:28:06

0:28:06

0:00:17

0:00:17

0:00:15

0:00:15

0:00:46

0:00:46

0:00:32

0:00:32

0:14:59

0:14:59

0:19:47

0:19:47

0:00:49

0:00:49

0:13:15

0:13:15

0:03:28

0:03:28

0:42:02

0:42:02

0:01:53

0:01:53

0:07:42

0:07:42

0:20:46

0:20:46

0:07:29

0:07:29

0:00:35

0:00:35

0:18:13

0:18:13

0:02:32

0:02:32

0:06:49

0:06:49

0:09:24

0:09:24

0:12:34

0:12:34

0:17:41

0:17:41