filmov

tv

difference between servo system and stepper system

Показать описание

Hello, thunderlaser as a professional laser machine manufacturer, always can help you if you have any questions about the laser machines.

What The Differences Between Stepper Motors And Servo Motors

Servo vs Stepper Motors

Stepper Motors vs Servo Motors: A Quick Comparison

How to Understand the Difference Between Servo & Stepper Systems

What's the difference between servo and stepper motors? | What The Tech?!

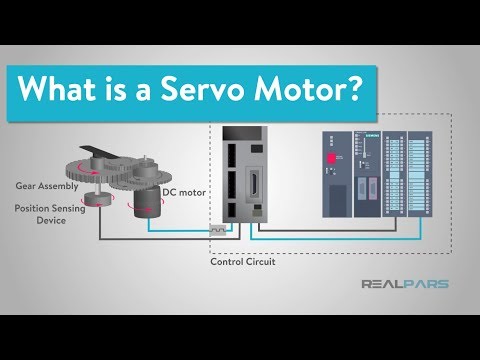

What is a Servo Motor and What Does It Do?

What is a Servo Motor and How it Works?

Servo System Comparison - Motion Control from AutomationDirect

Plastic Jar bottle blowing machine PET plastic bottle blow machine Taizhou Fupusi Machinery

difference between servo system and stepper system

What is a Servo System?

Drive System: Servo Drive VS. Variable Frequency Drive

Difference between servo and stepper motors in CNC router

How Servo Motor Works and Servo Motor Control?

Stepper Motors vs. Servo Motors - A ClearPath Demonstration

AC Servo Motor vs DC Servo Motor - Difference between AC Servo Motor and DC Servo Motor

Comparing Servo Motors vs Linear Motors | Which one to Choose | Supplied by John Brooks

Servo Motor Explained - 3D Animation

Servo Motors, how do they work?

2.4 Differences Between AC Servos and Inverters〈Your First AC Servo (6/14)〉

Introduction to Servo Motors and Motion Controllers

38s Video Tell You The Differences Between Stepper Motors And Servo Motors

What is Servo Mode vs One Shot AF - Explained in 2 mins + troubleshooting

Servo Motor vs Stepper Motor | What is best for your project │Motion Control Training

Комментарии

0:00:38

0:00:38

0:02:32

0:02:32

0:02:17

0:02:17

0:03:57

0:03:57

0:03:16

0:03:16

0:03:29

0:03:29

0:15:45

0:15:45

0:03:52

0:03:52

0:03:35

0:03:35

0:01:15

0:01:15

0:11:47

0:11:47

0:04:33

0:04:33

0:02:19

0:02:19

0:05:38

0:05:38

0:08:07

0:08:07

0:01:57

0:01:57

0:01:55

0:01:55

0:06:17

0:06:17

0:15:12

0:15:12

0:01:58

0:01:58

0:10:32

0:10:32

0:00:38

0:00:38

0:02:07

0:02:07

0:04:01

0:04:01