filmov

tv

CNC Machining Amazing Parts W/ Less Than $10K | Super Alloy Milling | Best of Tormach 2019

Показать описание

CNC Machining is what we do. We are Experts and on this channel we are bringing our knowledge and experience to YOU. Want more? Learn CAD, CAM & CNC Machining through our FREE TITANS of CNC: Academy.

___

___

FREE CNC Machining Academy. Join the Revolution:

Follow us on Instagram:

Like us on Facebook:

Join the conversation on our Facebook Group:

Connect with us on LinkedIn:

Follow our CEO, Titan Gilroy:

___

___

THANK YOU to our Partners who make this content possible:

#CNC #Machining #Machinist

MB017E7JAFBH4VC

CNC Machining Amazing Parts W/ Less Than $10K | Super Alloy Milling | Best of Tormach 2019

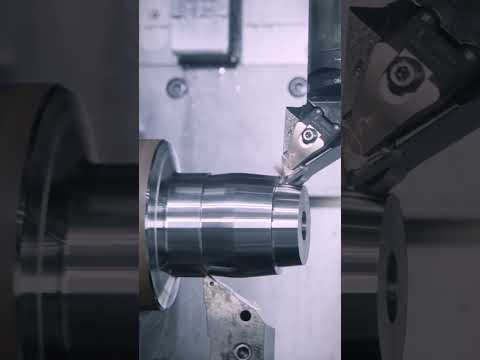

Impressive CNC Lathe Machine Turning

5-Axis CNC Machining

I Machined a 50 Million Dollar Part

cnc turning. #cncmachining #cncmachine #machining #cnc #cncturning #turning #parts

Incredible Machining: Parts Made In Seconds Using 8 Spindles

The TRUE COST of CNC machining!

Amazing CNC Turning: Watch Metal Transform in Seconds! #cncturning #cnc #cncmachining #mechanic

Crafting a little Birch Wooden Box/Chest (with a CNC)

Woodworking cnc router machine

One of the most Unreal parts on a CNC machine!

Secrets to Machining an Aerospace Part on a Tormach CNC Mill

Amazing Steel Pinch Turning Process

Making a Chessboard with Chess Pieces - CNC Milling and Turning - Machining

CNC Milling a Giant 3D Printed Ship

TOP 5 WAYS to EARN $100,000 as a CNC MACHINIST | DN Solutions

CNC machining Making Dragon 3D #cnc #cncmachining #cncmachine #5axis #cnc #machine #milling

Wooden 3d Cnc work high-speed work #cnc

CNC ... machine

CNC Machine Working Tool Video For Daily Job Work/BRAIN IQShort

EFFICIENT Pinch Turning on a CNC Machine

Inside Diameter CNC Turning

How My Desktop CNC Made Over $500,000 in 2 Years

Drill, Thread, and Chamfer with 1 Tool

Комментарии

0:04:32

0:04:32

0:00:10

0:00:10

0:00:14

0:00:14

0:05:44

0:05:44

0:00:09

0:00:09

0:13:49

0:13:49

0:11:17

0:11:17

0:00:29

0:00:29

0:01:00

0:01:00

0:00:20

0:00:20

0:00:49

0:00:49

0:16:24

0:16:24

0:00:10

0:00:10

0:14:13

0:14:13

0:00:14

0:00:14

0:07:55

0:07:55

0:00:23

0:00:23

0:00:12

0:00:12

0:00:21

0:00:21

0:00:27

0:00:27

0:00:08

0:00:08

0:00:08

0:00:08

0:11:34

0:11:34

0:00:23

0:00:23