filmov

tv

Friction Welding Job on the lathe

Показать описание

In this video, a broken shaft is friction welded to a threaded stud on the lathe.

The end result is a serviceable part and works well however there are a few things that we're learnt from this video and in future videos, we're going to try to do other friction welding videos. To help us develop the skill of friction welding on the lathe.

Currently, friction welding technology is seeing its place and welling together rocket engines by stir welling. To my understanding, they're using this technology because it does not add a 3rd party metal to the mix; in the end, we'll create a stronger weld free of flaws. No, I know this is a beaver table saw shaft, not a rocket engine but we have to start learning somewhere

check out the discussion

The end result is a serviceable part and works well however there are a few things that we're learnt from this video and in future videos, we're going to try to do other friction welding videos. To help us develop the skill of friction welding on the lathe.

Currently, friction welding technology is seeing its place and welling together rocket engines by stir welling. To my understanding, they're using this technology because it does not add a 3rd party metal to the mix; in the end, we'll create a stronger weld free of flaws. No, I know this is a beaver table saw shaft, not a rocket engine but we have to start learning somewhere

check out the discussion

Friction Welding Job on the lathe

Friction Stir Welding

First day on the job and you roll in like this?!

Discover How Friction Welding Works: We Go Behind The Scenes At Spenco

friction welding job in lathe machine

Friction Welding On The Lathe

Slow Motion: Incredible Friction Welding Process

Friction Stir Welding - Benefits for Industry

Linear Friction Welding for manufacturing of complex aerospace parts for TOD Project

Friction Welding

Linear Friction Welding

Friction welding on a lathe, what is it?

Rotary friction welder time lapse

Why aren’t you a welder yet? 😤

friction welding in lathe

Friction Stir Welding in Action 🎬

Friction Welding Strength Testing

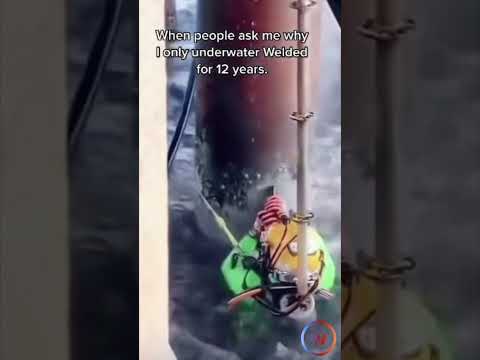

Day in the life of an Underwater Welder

Friction welding

Friction welding machine

Friction Stir Welding (FSW) plays a critical and unique role in the #welding of aluminium.

friction welding on lathe machine

184 Friction Welding with Brass Aluminum Titanium

4th shift is da best! #welder #welding #rigwelder #tig #tigtok

Комментарии

0:04:18

0:04:18

0:00:12

0:00:12

0:00:13

0:00:13

0:00:51

0:00:51

0:00:13

0:00:13

0:00:12

0:00:12

0:00:34

0:00:34

0:03:20

0:03:20

0:00:56

0:00:56

0:00:16

0:00:16

0:00:26

0:00:26

0:00:46

0:00:46

0:01:40

0:01:40

0:00:16

0:00:16

0:00:12

0:00:12

0:00:52

0:00:52

0:00:43

0:00:43

0:00:10

0:00:10

0:00:26

0:00:26

0:00:15

0:00:15

0:00:11

0:00:11

0:02:33

0:02:33

0:21:58

0:21:58

0:00:12

0:00:12