filmov

tv

Do Wood Treatments Really Work? UNEXPECTED RESULTS

Показать описание

3 years ago I set up an experiment to find out if wood treatments actually work to protect timber from rot, decay and wood boring insects. I wanted to test pressure treated / tanalised wood and also self treated wood with a wood preserver product. The results from these tests really surprised me!

Thanks to @ProperDIY for the footage of the rotten fence post

0:00 Intro

0:14 Setting The Experiment Up

1:32 The Past 3 Years

1:49 Why Do We Treat Exterior Wood?

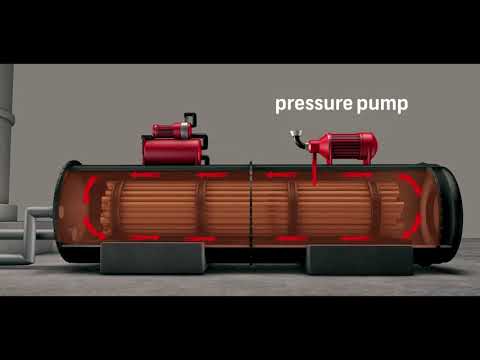

3:16 The Treatment Options

6:31 The Test Results

12:25 Grain Tightness

12:43 What We've Learned

🔴My channel is supported by Milwaukee🔴

#woodworking #treatment #preserver

Thanks for watching! Please subscribe, click like if you like, and hit the bell icon for future video notifications

🔨 MY TOOLS 🔨

For links to the tools I use, plus some of my favourite consumables, finishes and more see links below. As an Amazon associate I may earn from qualifying purchases

🤝 HELP SUPPORT THE CHANNEL 🤝

💰 SHOP 💰

🎧 WORKSHOP BANTER PODCAST 🎧

Also available on Spotify, Apple, Google and most other podcast platforms

🔗 LINKS: 🔗

Instagram: @ragnbonebrown

Thanks to @ProperDIY for the footage of the rotten fence post

0:00 Intro

0:14 Setting The Experiment Up

1:32 The Past 3 Years

1:49 Why Do We Treat Exterior Wood?

3:16 The Treatment Options

6:31 The Test Results

12:25 Grain Tightness

12:43 What We've Learned

🔴My channel is supported by Milwaukee🔴

#woodworking #treatment #preserver

Thanks for watching! Please subscribe, click like if you like, and hit the bell icon for future video notifications

🔨 MY TOOLS 🔨

For links to the tools I use, plus some of my favourite consumables, finishes and more see links below. As an Amazon associate I may earn from qualifying purchases

🤝 HELP SUPPORT THE CHANNEL 🤝

💰 SHOP 💰

🎧 WORKSHOP BANTER PODCAST 🎧

Also available on Spotify, Apple, Google and most other podcast platforms

🔗 LINKS: 🔗

Instagram: @ragnbonebrown

Комментарии

0:14:17

0:14:17

0:05:11

0:05:11

0:02:26

0:02:26

0:12:50

0:12:50

0:07:06

0:07:06

0:09:58

0:09:58

0:14:26

0:14:26

0:03:51

0:03:51

0:04:27

0:04:27

0:03:31

0:03:31

0:02:17

0:02:17

0:00:14

0:00:14

0:03:58

0:03:58

0:01:01

0:01:01

0:08:19

0:08:19

0:06:48

0:06:48

0:12:21

0:12:21

0:07:30

0:07:30

0:21:08

0:21:08

0:06:21

0:06:21

0:13:36

0:13:36

0:11:19

0:11:19

0:06:54

0:06:54

0:01:36

0:01:36