filmov

tv

The Incredible Strength of Bolted Joints

Показать описание

---

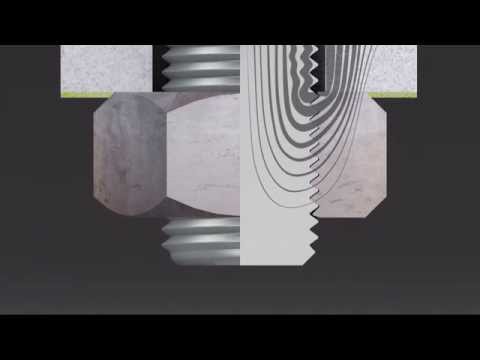

This video takes a detailed look at bolted joints, and how preload, the tensile force that develops in a joint as it is torqued, can significantly improve the performance of a joint.

The video covers tension joints, shear joints, and joints that are subjected to combined tensile and shear loads.

It also explores the different methods that can be used to control the amount of preload applied to a joint, including the torque, turn-of-nut and ultrasonic measurement methods.

---

This will allow me to create more high quality videos covering a range of engineering topics.

---

The Efficient Engineer is a channel aimed at mechanical and civil engineers. The mission is to simplify engineering concepts, one video at a time!

The Incredible Strength of Bolted Joints

Bolted joint diagramm explained with 3D Animation | made with Blender

The Incredible Strength Of Bolts and Joints ||Bolts|| ||Joints||

Bolt Preloading & Torque | Static Strength of Bolted Joints | Load Factor | Joint Separation Fac...

| High Tensile Fastener | The Incredible Strength of Bolted Joints | 8.8,10.9,12.9 | Uses | Torque |

Bolted joint diagram – Short explanation close to PERFECT!

inner mechanism of Rawl Bolts | Fasteners Bolt #shorts

Intro to Preloaded Bolted Joint Design — Lesson 1

In the Lab: Fundamentals of Bolted Joints: Secrets | Atlas Copco USA

What are Bolted Joints? || Fasteners: Bolted Joints Course Preview

Introduction To Bolted Joint Design: A Step by Step Approach

How to Calculate Bolt Value/Strength of Bolt | Bolted Connection | Design of Steel Structures

Mechanics of Bolted Connections — Lesson 2, Part 1

Importance of Correctly Torqueing Bolted Joints

How to Calculate Bolt Value/Strength of Bolt | Bolted Connection | Design of Steel Structures

Do Carriage Bolts Have Shear Strength

Bolted Joint Analysis and Design

Strength of Bolt and Bolted Joint Lecture 11 (Steel)

KEVIN HART vs USAIN BOLT ⚡ #PokerStars #HartvsBolt

Mechanics of Bolted Connections — Lesson 2, Part 2

How to Calculate Shear Force on a Bolted Connection | FEA for beginners | SolidWorks Simulation

Design Bearing Capacity of Bolted Connection | Design of Steel Structure | Part 14

Eccentrically Loaded Bolted Joints Design Problem 2&3

Bolted Connection | Eccentrically Loaded | Safety Factor | FEA for beginners | SolidWorks Simulation

Комментарии

0:17:58

0:17:58

0:03:46

0:03:46

0:18:23

0:18:23

1:05:21

1:05:21

0:09:17

0:09:17

0:07:38

0:07:38

0:00:29

0:00:29

0:12:53

0:12:53

0:05:03

0:05:03

0:03:21

0:03:21

0:14:15

0:14:15

0:16:51

0:16:51

0:03:56

0:03:56

0:00:51

0:00:51

0:12:30

0:12:30

0:00:27

0:00:27

0:42:23

0:42:23

0:11:07

0:11:07

0:00:58

0:00:58

0:06:10

0:06:10

0:10:48

0:10:48

0:05:42

0:05:42

0:16:29

0:16:29

0:14:10

0:14:10