filmov

tv

Air Lock Prevention Tips

Показать описание

Zoeller Pump Company offers some insights to preventing the common issue of airlock in your sump pump. Learn what to look for and how to prevent this from happening when installing sump pumps.

Air Lock Prevention Tips

How to Deal with an Airlock

How to clear air lock in taps! #plumbing #diyequipment #diy #plumping #howto

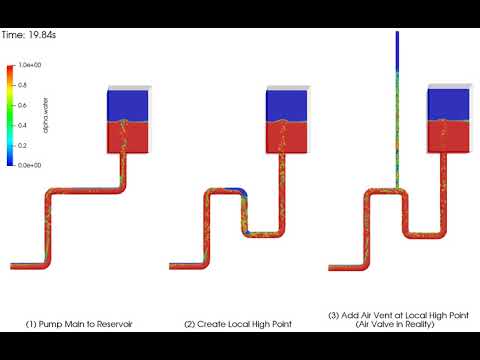

2020-10 - Airlock and Waterfall in Pipe

What is Air Lock?

How do you get air out of water pipes in your house?

How to clear Air locked hot water system

How to Prevent Airlock on the Little Giant 6 Series

How to Prevent Motorcycle THEFT

Unblock an airlock in the hot water system in ten seconds - no tools needed. (See disclaimer below.)

Release Gas in the Body, Support Digest System | Press this Acupressure Point (PC6) Daily #shorts

Water Pump Airlock Procedure

How To Fix A HOT TUB Air Lock FAST

TOP TIP Remove filter air lock

king idea.pressure bottle connect pvc pipe big to small many people know this!

Sump Pump Testing and Running - Breather Hole / Weep Hole Preventing Air Lock!

It even Happens to Me...How to fix an AirLock in a Hot Tub... Arizona Hot Tub Factory

How to Unclog Your Ears Super Fast! Dr. Mandell

HOT TUB PUMP - Clear an Airlock after refill!

How to get rid of an air lock on a small circulation pump (getting into equipment compartment)

How to fix air lock on water pump in Ajman Uptown

Trick Free electricity | I turn PVC pipe into a water pump at home free no need electricity power

Hot Spring 'Protection Mode' Quick Fix - Air Lock

BEST way to remove airlock in radiator (remove air bubbles)

Комментарии

0:02:12

0:02:12

0:01:50

0:01:50

0:00:18

0:00:18

0:00:36

0:00:36

0:09:46

0:09:46

0:00:28

0:00:28

0:01:37

0:01:37

0:02:38

0:02:38

0:09:41

0:09:41

0:01:37

0:01:37

0:00:50

0:00:50

0:01:46

0:01:46

0:05:31

0:05:31

0:00:29

0:00:29

0:00:36

0:00:36

0:00:40

0:00:40

0:06:14

0:06:14

0:00:52

0:00:52

0:03:50

0:03:50

0:01:41

0:01:41

0:08:02

0:08:02

0:01:00

0:01:00

0:01:45

0:01:45

0:01:21

0:01:21