filmov

tv

What is Air Lock?

Показать описание

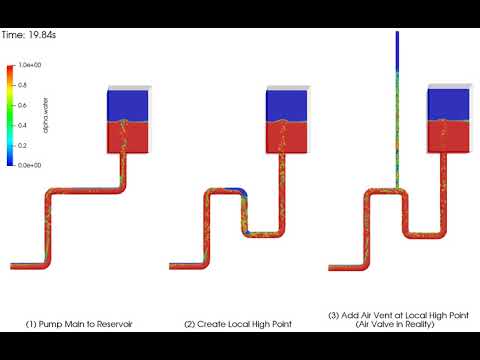

A demonstration and brief explanation of air lock in fluid pipelines.

If you assume that gasses don’t get into pipes or that they can’t constrict the flow, you might design a pipeline that doesn’t work. Luckily for engineers, this is a well-known phenomenon in pipe systems. It’s just one of the complexities that come with the job and we’ve come up a with a lot of creative ways to overcome it.

Writing/Editing/Production: Grady Hillhouse

Director: Wesley Crump

Tonic and Energy by Elexive is licensed under a Creative Commons Attribution License

This video is sponsored by HelloFresh.

If you assume that gasses don’t get into pipes or that they can’t constrict the flow, you might design a pipeline that doesn’t work. Luckily for engineers, this is a well-known phenomenon in pipe systems. It’s just one of the complexities that come with the job and we’ve come up a with a lot of creative ways to overcome it.

Writing/Editing/Production: Grady Hillhouse

Director: Wesley Crump

Tonic and Energy by Elexive is licensed under a Creative Commons Attribution License

This video is sponsored by HelloFresh.

What is Air Lock?

How to Deal with an Airlock

Are Airlocks Actually Deadly?

Waterfall Flow & Airlocks in Pipes Explained

A 3D view of material flow in an MD Series rotary airlock valve

Air Lock Prevention Tips

2020-10 - Airlock and Waterfall in Pipe

How do you get air out of water pipes in your house?

Beginner's guide to fermentation, airlocks and what to look for

fixing an airlock after a mains water outage

AirLock system in Pharmaceutical Industries

How to clear Air locked hot water system

It even Happens to Me...How to fix an AirLock in a Hot Tub... Arizona Hot Tub Factory

Montering av Airlock 100 Fönsterkit

Air lock | what is the purpose of air lock | voice of kayani

Airlocks and Blowoff Tubes for Brewing

Overflowing Airlock

How Air Lockers Work

How To Fix A HOT TUB Air Lock FAST | Swim University

Water Pump Airlock Procedure

Hydraulic model testing Air pockets in pipelines

how to make Simple homemade Airlock for wine & Beer meking

HOT TUB PUMP - Clear an Airlock after refill!

BEST way to remove airlock in radiator (remove air bubbles)

Комментарии

0:09:46

0:09:46

0:01:50

0:01:50

0:11:16

0:11:16

0:16:19

0:16:19

0:00:25

0:00:25

0:02:12

0:02:12

0:00:36

0:00:36

0:00:28

0:00:28

0:05:40

0:05:40

0:04:58

0:04:58

0:02:12

0:02:12

0:01:37

0:01:37

0:06:14

0:06:14

0:01:50

0:01:50

0:04:34

0:04:34

0:09:49

0:09:49

0:09:20

0:09:20

0:01:47

0:01:47

0:05:31

0:05:31

0:01:46

0:01:46

0:06:37

0:06:37

0:05:09

0:05:09

0:03:50

0:03:50

0:01:21

0:01:21