filmov

tv

EEVblog #1165 - Cypres Parachute Safety AAD Teardown

Показать описание

DejaVu. Dave revisits the new generation Cypres 2 parachute Automatic Activation Device and tears it down.

A safety device that automatically activates your parachute at a pre-set altitude. It has saved over 4000 lives to date.

Bitcoin Donations: 38y7DE8HEHNj8fGDtUr4PkCn9nWxiorvvy

Litecoin: ML7oQokTwB38bgzzjLDbRV97HKAHuwRfHA

Ethereum: 0x11AceA38DCA9DbFfB4F35f3F746af65F9dED28ce

Support the EEVblog through Patreon!

Buy anything through that link and Dave gets a commission at no cost to you.

Stuff I recommend:

Donate With Bitcoin & Other Crypto Currencies!

A safety device that automatically activates your parachute at a pre-set altitude. It has saved over 4000 lives to date.

Bitcoin Donations: 38y7DE8HEHNj8fGDtUr4PkCn9nWxiorvvy

Litecoin: ML7oQokTwB38bgzzjLDbRV97HKAHuwRfHA

Ethereum: 0x11AceA38DCA9DbFfB4F35f3F746af65F9dED28ce

Support the EEVblog through Patreon!

Buy anything through that link and Dave gets a commission at no cost to you.

Stuff I recommend:

Donate With Bitcoin & Other Crypto Currencies!

EEVblog #1165 - Cypres Parachute Safety AAD Teardown

The Stratos Jump with a view on CYPRES LogData

CYPRES Cutter Stress Test

My Cypress AAD expired

Q&A with CYPRES

Myth Busted - Can a Cypres cut through wire?

How to Increase your CYPRES activation altitude

Сборка парашютной системы подсоединение ОП Кентавр Т9

EEVblog #1163 - Xmas Mailbag

#SkydiveSonora #Morgan #Firstjump #tandem #icaruscanopy #cypress2

EEVblog #1164 - Xbox Engineering Baptism Of Fire

EEVblog #1161- Automated Coffee Machine Dumpster Teardown

Cypres fire & reserve ride skydiving #skydive

Do you know your AAD well enough? - 5 best practices

2 out cypress fire at 750'

Skydiving AAD Must Know Maintenance Tips by Cypres AAD (2019)

EEVblog #1172 - TRIAC Testing (WEP Meltdown Part 2)

EEVblog #1166 - Amazing 1980's Touch Screen Calculator Watch!

Vigil-2 / CYPRES AAD Fired. Reserve Parachute Automatic Opening

eevBLAB #28 - How To Get A Product Designed

EEVblog #455 - Auction Bonanza

CYPRES DemoTeam Guiness World Record Jump

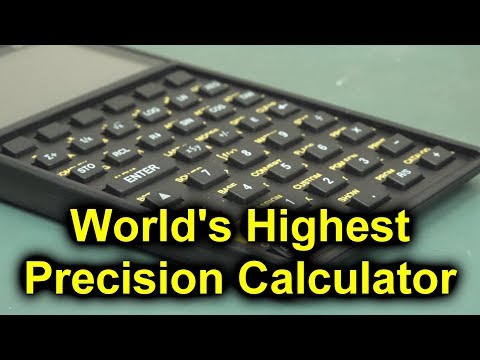

EEVblog #1159 - World's Most Precise Pocket Calculator

EEVblog #1142 - EEVblog LAB Tour - Before

Комментарии

0:33:03

0:33:03

0:10:53

0:10:53

0:07:03

0:07:03

0:12:21

0:12:21

0:53:55

0:53:55

0:01:37

0:01:37

0:06:48

0:06:48

0:04:35

0:04:35

0:54:48

0:54:48

0:06:03

0:06:03

0:29:59

0:29:59

0:29:14

0:29:14

0:02:09

0:02:09

0:06:17

0:06:17

0:01:40

0:01:40

0:07:31

0:07:31

0:16:47

0:16:47

0:19:47

0:19:47

0:03:10

0:03:10

0:20:45

0:20:45

0:19:01

0:19:01

0:07:29

0:07:29

0:17:57

0:17:57

0:17:07

0:17:07