filmov

tv

Spraying Finish in my Finishing Room

Показать описание

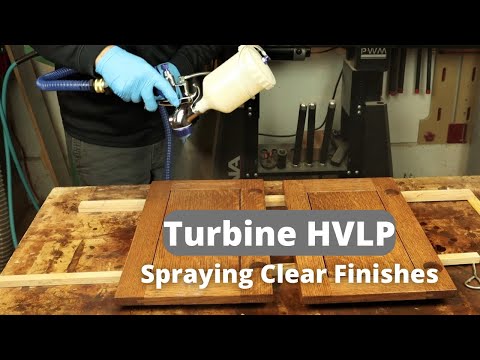

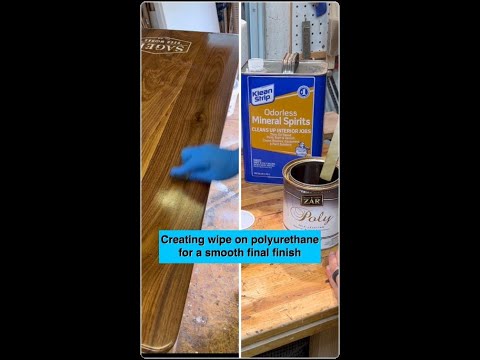

Ep253: In this episode we take you on an adventure, heading downstairs to the finishing room, which is a first - live from the “downstairs shop.” I will show you the setup of my finishing room and demonstrate how I spray finish so easily in this space. I’m spoiled to have an area away from the usual dust of the shop, but after this spray demo, maybe you will find a way to set apart an area for this super efficient finishing method.

Experience Woodworking with Tom McLaughlin:

SUBSCRIBE and ring the bell here to be notified of live events and video uploads.

EPISODE LINKS:

RELATED VIDEO RESOURCES:

~~~~~~~

Enjoy SHOP NIGHT LIVE each week, streaming from Tom's shop for the purpose of passing on the craft of woodworking. Episodes are filmed LIVE so questions can be asked and answered in real time. They are edited soon after for those who enjoy the overall content.

Also join us here:

Instagram: @EpicWoodworking

Facebook: @EpicWoodworking

YouTube: @EpicWoodworking

Tiktok: @EpicWoodworking

~~~~~~~

FTC Disclosure: In general, the links we provide through Amazon are affiliate links, which means we will receive a slight commission if you purchase something using that link. Affiliate arrangements are not a focus for us, but we do want you to be aware of this one.

Experience Woodworking with Tom McLaughlin:

SUBSCRIBE and ring the bell here to be notified of live events and video uploads.

EPISODE LINKS:

RELATED VIDEO RESOURCES:

~~~~~~~

Enjoy SHOP NIGHT LIVE each week, streaming from Tom's shop for the purpose of passing on the craft of woodworking. Episodes are filmed LIVE so questions can be asked and answered in real time. They are edited soon after for those who enjoy the overall content.

Also join us here:

Instagram: @EpicWoodworking

Facebook: @EpicWoodworking

YouTube: @EpicWoodworking

Tiktok: @EpicWoodworking

~~~~~~~

FTC Disclosure: In general, the links we provide through Amazon are affiliate links, which means we will receive a slight commission if you purchase something using that link. Affiliate arrangements are not a focus for us, but we do want you to be aware of this one.

Комментарии

0:17:53

0:17:53

0:06:33

0:06:33

0:09:39

0:09:39

0:07:56

0:07:56

0:00:16

0:00:16

0:12:12

0:12:12

0:09:11

0:09:11

0:05:19

0:05:19

0:19:03

0:19:03

0:00:34

0:00:34

0:21:26

0:21:26

0:02:29

0:02:29

0:16:44

0:16:44

0:03:12

0:03:12

0:53:01

0:53:01

0:12:59

0:12:59

0:02:44

0:02:44

0:00:21

0:00:21

0:01:36

0:01:36

0:00:33

0:00:33

0:13:15

0:13:15

0:00:20

0:00:20

0:00:22

0:00:22

0:05:00

0:05:00