filmov

tv

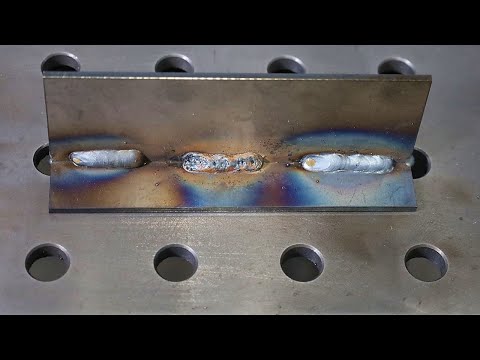

COMMON MIG WELDER FAULTS AND HOW TO FIX THEM

Показать описание

Here's a few tips on how to troubleshoot any problems your having with your mig welder. Give it a wathch and you will be back up and running in no time.

My names Matt Urch and I own and run Urchfab welding and fabrication.

I specialise in custom automotive fabrication from building roll cages to complete one off builds.

I built the worlds most unique and oldest drift car known as the drift rod which can be found on my channel.

So if your into grinding, welding, fabricating, drifting, going fast etc, your in the right place!

My names Matt Urch and I own and run Urchfab welding and fabrication.

I specialise in custom automotive fabrication from building roll cages to complete one off builds.

I built the worlds most unique and oldest drift car known as the drift rod which can be found on my channel.

So if your into grinding, welding, fabricating, drifting, going fast etc, your in the right place!

COMMON MIG WELDER FAULTS AND HOW TO FIX THEM

How NOT TO Weld: Most Common MIG Welding Mistakes

Top 5 MIG welder common problems issues faults and easy fixes

Common Mistakes the New MIG welders Make and How to Avoid Them - Eastwood

5 Welding Problems Fixed: Welding Basics for Beginners

Troubleshooting Common Industrial MIG Welding Problems

Don't Throw Away Your Broken Welding Machine - Repair It!

How To Avoid Common Wire Feeding Issues

How NOT to MIG weld: Variables in MIG welding

Fix a Mig welder your guide to troubleshooting a MIG welder (any brand) not working or broken

5 MIG Welding Mistakes I Made as a Beginner

MIG welder troubleshooting, fault finding, repair, testing the transformer, switch, choke, rectifier

DON'T Do These 7 Things When MIG WELDING (Common Mistakes to Avoid!)

Troubleshooting MIG wire feeding issues - Weldpro Tips

How to Troubleshoot a Bad MIG Weld

How To Avoid Contact Tip Issues When MIG Welding

Mig Welding troubleshooting tips

What are the most common MIG welding mistakes? #welding #mig

Fix This MIG Welding Problem

MIG Welding Porosity: Common Causes & Solutions

Why Is My MIG Welder Doing This? Fix Common Issues FAST!

Common Mistakes in Mig Welding Pt.3. Repost from @dr.weldz(TikTok) #yeswelder #shorts #migwelding

Top 5 common faults and easy fixes MMA ARC Stick welders

#tack #weld on thin square tube with large gap and common mistakes in #mig #gmaw #welding #welder

Комментарии

0:11:32

0:11:32

0:16:44

0:16:44

0:02:37

0:02:37

0:05:01

0:05:01

0:07:28

0:07:28

0:07:21

0:07:21

0:00:52

0:00:52

0:01:35

0:01:35

0:11:01

0:11:01

0:16:53

0:16:53

0:08:27

0:08:27

0:07:46

0:07:46

0:10:05

0:10:05

0:05:38

0:05:38

0:04:10

0:04:10

0:01:22

0:01:22

0:00:16

0:00:16

0:00:17

0:00:17

0:04:42

0:04:42

0:01:26

0:01:26

0:02:33

0:02:33

0:00:54

0:00:54

0:03:42

0:03:42

0:00:12

0:00:12