filmov

tv

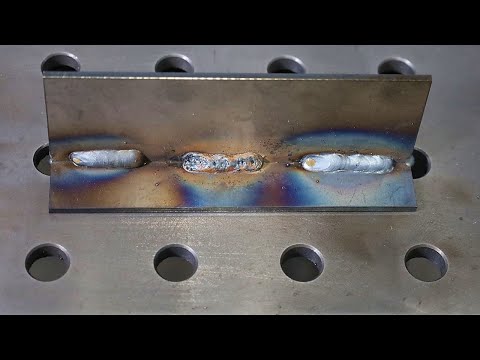

Fix This MIG Welding Problem

Показать описание

Lumpy welds are a bummer...Let's fix it!

Learn faster with an online welding course:

Other Helpful Videos:

Gas Metal Arc Welding (GMAW), also known as Metal Inert Gas (MIG) welding is the best welding process for many different applications. This tutorial provides the solution to a very common MIG welding problem beginners face.

Learn faster with an online welding course:

Other Helpful Videos:

Gas Metal Arc Welding (GMAW), also known as Metal Inert Gas (MIG) welding is the best welding process for many different applications. This tutorial provides the solution to a very common MIG welding problem beginners face.

Fix This MIG Welding Problem

How NOT TO Weld: Most Common MIG Welding Mistakes

Troubleshooting MIG wire feeding issues - Weldpro Tips

Why Is It Popping? | MIG Welder Machine Settings

MiG Welding Wire Hard to Start? Problem Solved✅ #mig #weld #shorts

Mig Welding troubleshooting tips

FIXING A MIG WELDER

5 Welding Problems Fixed: Welding Basics for Beginners

Mig welding machine without gasless flux cored wire

Fix a Mig welder your guide to troubleshooting a MIG welder (any brand) not working or broken

How to Troubleshoot a Bad MIG Weld

MIG Welding Porosity: Common Causes & Solutions

Troubleshooting Common Industrial MIG Welding Problems

(HELP) I Can't See My Mig WELDS (Top 5 Tips)

Lincoln 180 Welder Fix!

How To Avoid Contact Tip Issues When MIG Welding

MIG Welding Quick Tip - How to Fix Excessive Spatter - MIG Welding from Eastwood

COMMON MIG WELDER FAULTS AND HOW TO FIX THEM

Untold Flux Core Welding Wire Secrets

Top 5 MIG welder common problems issues faults and easy fixes

What Causes Lack Of Fusion?

How To Remove A Wire Stuck In A Welding Torch In 10 Seconds

TUTORIALS WITH WILL

#1 Tip and Trick to Improve Flux Core Welding

Комментарии

0:04:42

0:04:42

0:16:44

0:16:44

0:05:38

0:05:38

0:08:05

0:08:05

0:00:16

0:00:16

0:00:16

0:00:16

0:00:59

0:00:59

0:07:28

0:07:28

0:00:59

0:00:59

0:16:53

0:16:53

0:04:10

0:04:10

0:01:26

0:01:26

0:07:21

0:07:21

0:11:47

0:11:47

0:00:30

0:00:30

0:01:22

0:01:22

0:00:50

0:00:50

0:11:32

0:11:32

0:01:00

0:01:00

0:02:37

0:02:37

0:00:15

0:00:15

0:00:59

0:00:59

0:00:55

0:00:55

0:04:16

0:04:16