filmov

tv

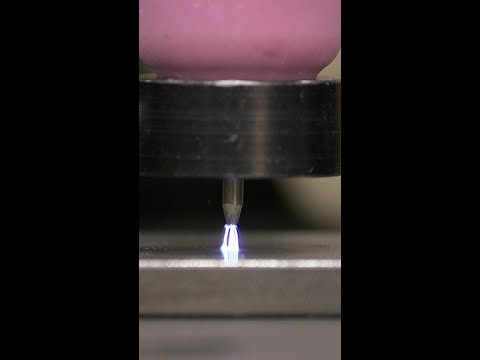

🔥 TIG Welding 1.6mm Stainless Fillets (Viewer Request)

Показать описание

We had a request to weld up some 1.6mm (16 gauge) Stainless Steel using the TIG process and no pulse. The trick to TIG welding thin Stainless is to have a fast travel speed. The slower you go, the more oxides you are going to get, so hammer down and go!

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

VIDEO SCHEDULE:

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

► MIG Monday: New Videos every Monday!

► TIG Time: New Videos every Friday!

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

EQUIPMENT WE USE:

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

► ESAB Power Sources: www.ESAB.com

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

JOIN US ON:

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬ #welddotcom

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

VIDEO SCHEDULE:

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

► MIG Monday: New Videos every Monday!

► TIG Time: New Videos every Friday!

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

EQUIPMENT WE USE:

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

► ESAB Power Sources: www.ESAB.com

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

JOIN US ON:

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬

▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬▬ #welddotcom

🔥 TIG Welding 1.6mm Stainless Fillets (Viewer Request)

HOW TO TIG WELD STAINLESS STEEL FOR BEGINNERS

Beginner TIG welders NEED to know this...

New Tig Welding Tricks to Solve Crazy Problems ! 0.4 mm thin stainless steel sheets with open gaps

How to TIG weld stainless - 5 tips in 3 minutes

TIG Welding Stainless Steel: A Beginner's Guide

Why are my tig welds GRAY? (It's not what you think...)

TFS: The Secret to Perfect Stainless TIG Welds

How to TIG Weld Stainless Steel - Tips, Tricks, Pulse, and Machine Setup!

How to Avoid Mistakes When TIG Welding 1mm Stainless Steel Sheet Butt Joints

TIG weld 6G🤨🧐🧐root pasd welding

TIG Welding Techniques for Stainless Tee Joint

the 3 BEST SETTINGS to start tig welding STAINLESS

Stainless Steel TIG Welding #shorts

Stainless Steel Welding Tips - TIG Welding

Tips for Tig Welding Stainless

Fixing your settings for stainless tig welding? Watch this first🔥

Sanitary Tube Stainless TIG Welding - Autogenous No Filler #shorts

How to TIG WELD Stainless Steel Tube + Tips & Tricks | Automotive Fabrication | GTAW CUPS

TIG welding stainless steel headers

How To Tig Weld Stainless in 3 Hours- COMPLETE LESSON

tig welding#stainless steel welding#304 #ss railing#ss #youtubeshorts #youtube viral#argon

the FIRST thing you should learn tig welding

Stop doing this to yourself tig welding! Follow this tip! #shorts

Комментарии

0:06:01

0:06:01

0:10:11

0:10:11

0:00:18

0:00:18

0:06:20

0:06:20

0:03:02

0:03:02

0:08:45

0:08:45

0:07:05

0:07:05

0:21:24

0:21:24

0:14:30

0:14:30

0:08:11

0:08:11

0:00:30

0:00:30

0:06:06

0:06:06

0:11:32

0:11:32

0:00:27

0:00:27

0:09:18

0:09:18

0:17:10

0:17:10

0:01:00

0:01:00

0:00:25

0:00:25

0:09:17

0:09:17

0:00:16

0:00:16

0:24:55

0:24:55

0:00:16

0:00:16

0:03:20

0:03:20

0:00:59

0:00:59