filmov

tv

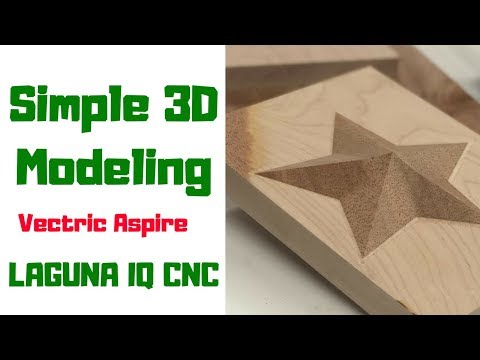

Simple 3D Modeling with Vectric Aspire // Laguna IQ CNC

Показать описание

10:02 Straight to the Action!

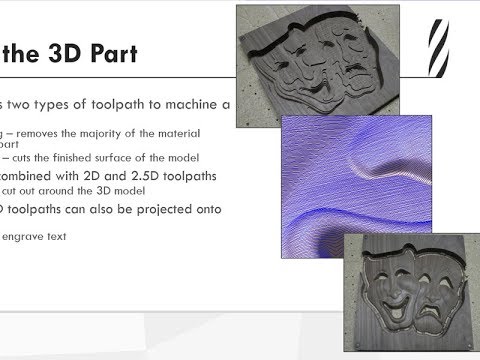

Today I will make a simple 3D modeling project with Vectric Aspire software and the Laguna IQ CNC machine. 3D modeling can be intimidating, but we are going to have some fun and make a simple shape using the Aspire software.

I've been making these CNC videos for a while now. I usually show a successful outcome. Today is not the case. I made a few mistakes on this one and will point them out in the video and here.

1. The wedges that hold the material were sliding out making the material move a little. I fixed it before the finishing pass so there wasn't an effect on the outcome of the project.

2. While looking at the tool path on the model. I didn't notice that the edge of the material would be cut. I didn't take the time to make sure everything was ok. So I found out the hard way. I put a clip and explanation in the software part of the video.

3. I used some scrap wood for this project that turned out to not be parallel. So the final project has dark wood showing through. Explained at the end of the video.

As always, Thank you for watching my videos and feel free to ask questions or just say Hello in the comments section.

Any Questions for Laguna Call Directly HERE: 1-949-527-6160

PLEASE SUPPORT MY CHANNEL!

.

Today I will make a simple 3D modeling project with Vectric Aspire software and the Laguna IQ CNC machine. 3D modeling can be intimidating, but we are going to have some fun and make a simple shape using the Aspire software.

I've been making these CNC videos for a while now. I usually show a successful outcome. Today is not the case. I made a few mistakes on this one and will point them out in the video and here.

1. The wedges that hold the material were sliding out making the material move a little. I fixed it before the finishing pass so there wasn't an effect on the outcome of the project.

2. While looking at the tool path on the model. I didn't notice that the edge of the material would be cut. I didn't take the time to make sure everything was ok. So I found out the hard way. I put a clip and explanation in the software part of the video.

3. I used some scrap wood for this project that turned out to not be parallel. So the final project has dark wood showing through. Explained at the end of the video.

As always, Thank you for watching my videos and feel free to ask questions or just say Hello in the comments section.

Any Questions for Laguna Call Directly HERE: 1-949-527-6160

PLEASE SUPPORT MY CHANNEL!

.

Комментарии

0:14:57

0:14:57

0:16:40

0:16:40

0:22:26

0:22:26

0:00:13

0:00:13

0:17:29

0:17:29

0:13:09

0:13:09

0:13:59

0:13:59

0:46:22

0:46:22

0:34:40

0:34:40

0:11:32

0:11:32

0:13:30

0:13:30

0:30:09

0:30:09

0:34:09

0:34:09

1:45:10

1:45:10

0:21:48

0:21:48

0:12:12

0:12:12

1:01:01

1:01:01

0:11:00

0:11:00

0:34:19

0:34:19

0:15:54

0:15:54

0:06:03

0:06:03

0:00:33

0:00:33

0:38:32

0:38:32

0:21:25

0:21:25