filmov

tv

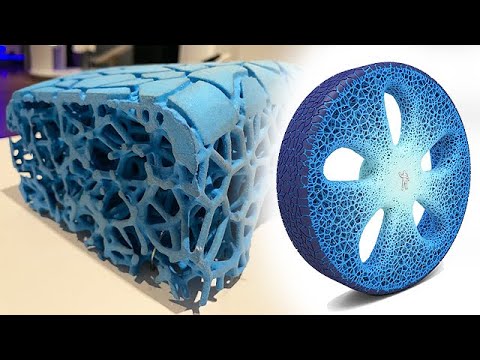

3D PRINTED TIRES... Will They Last??

Показать описание

Check out KyWoo3D using the link and coupon code below! Purchases using the link below help benefit the channel and make future projects possible.

$30 Off Coupon Code: KYMR$30OFF

Follow me for more updates on projects:

Links to stuff I use (affiliate links):

$30 Off Coupon Code: KYMR$30OFF

Follow me for more updates on projects:

Links to stuff I use (affiliate links):

3D PRINTED TIRES... Will They Last??

I 3D Printed RC Car Tires... Will they survive???

3D Printed RC Car Tires...Will they work?

Michelin 3D Printed Airless Tire

Airless tires: a gimmick or the next big thing in the car industry? #3dprint #cars #engineering

3D Printed Airless Tires is the future of Cars

3D Printing Custom Tires for my R/C Car - Prop: 3D

How To: 3D Printing Custom Wheels and Tyres for scale models with the Creality Halot-One

Printing TPU with the Creality Ender-3 v3PLUS

3D print your own bike tires! #mtb #cycling #bikeshorts

Airless Honeycomb TPU Tires for Electric Skateboards! 3D printed.

Michelin's 3D printed VISION Tire first look

3D printed Lego Rims for Liebherr and RC4WD Tires 🔥

3D Printed Wheels and Tires, A Review--Boneshaker

I designed & 3d printed these flexible “airless” tires for powerful brushless hub motors. #robot...

3D printed airless tires actually work?!?!

Big Airless 3D Printed Tires

3D Printing Flexible Rubber Like Tyres for Your Scale Models with Resione FX60 Flexible Resin

3d printing custom tires for LEGO vehicles - fixing the Technic Batmobile!

3D printed Electric Skateboard ABS rims & TPU tires!

3D printed tires amazing designs and innovation

Don't throw away all your 3D printing filament ends! Do this!

How to Make RC Silicone Tires with 3D Printed Molds

3D Printed Tires for RC-Car (Made of TPU)

Комментарии

0:08:04

0:08:04

0:08:59

0:08:59

0:10:15

0:10:15

0:03:35

0:03:35

0:00:47

0:00:47

0:02:12

0:02:12

0:07:07

0:07:07

0:17:17

0:17:17

0:13:28

0:13:28

0:00:26

0:00:26

0:03:26

0:03:26

0:03:56

0:03:56

0:00:24

0:00:24

0:12:24

0:12:24

0:00:24

0:00:24

0:00:40

0:00:40

0:00:15

0:00:15

0:09:29

0:09:29

0:09:15

0:09:15

0:06:12

0:06:12

0:00:31

0:00:31

0:00:56

0:00:56

0:08:06

0:08:06

0:01:07

0:01:07