filmov

tv

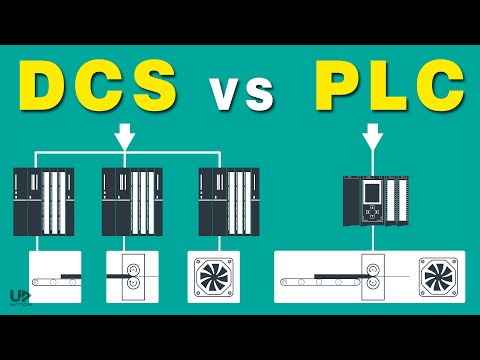

PLC vs DCS | What is the Difference Between PLC and DCS? | 2021

Показать описание

PLC VS DCS | Key Differences #PLC #DCS #differences

==========================

Difference between PLC and DCS

==========================

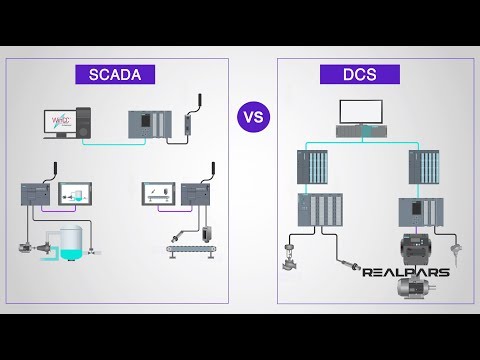

PLC for Discrete control like automobile industry....DCS for analog control like oil and gas

PLC centralized DCS distributed control System

High Response time DCS,

Monitoring OF DCS, PLC Need HMI

DCS predefined function

Response time of PLC is high

DCS takes much longer to process data, so it’s not the right solution when response times are critical safety systems require a separate controller.

A PLC can only handle a few thousand I/O points or less

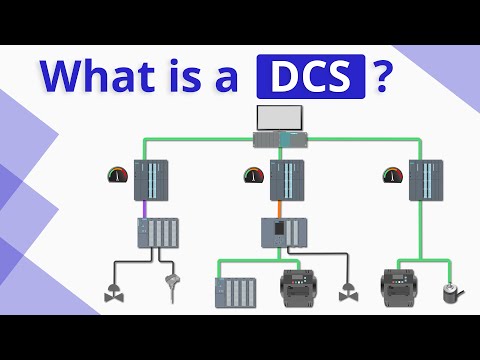

DCS, which can handle many thousands of I/O points and more easily accommodate new equipment

Redundancy in DCS

Frequent process changes

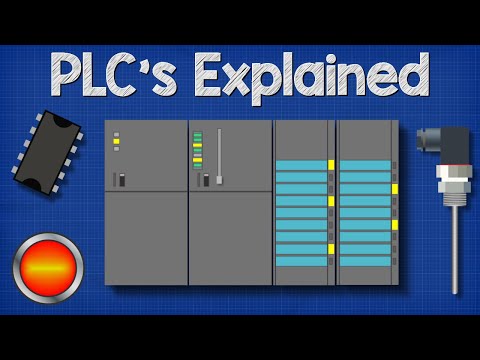

PLCs are best applied to a dedicated process that doesn’t change often.

Logic development

PLC can programmed be programmed based on our application.

DCS comes with built-in control functions

Cost of DCS is high

PLC or DCS Which is Right for Your Operation?

==========================

Difference between PLC and DCS

==========================

PLC for Discrete control like automobile industry....DCS for analog control like oil and gas

PLC centralized DCS distributed control System

High Response time DCS,

Monitoring OF DCS, PLC Need HMI

DCS predefined function

Response time of PLC is high

DCS takes much longer to process data, so it’s not the right solution when response times are critical safety systems require a separate controller.

A PLC can only handle a few thousand I/O points or less

DCS, which can handle many thousands of I/O points and more easily accommodate new equipment

Redundancy in DCS

Frequent process changes

PLCs are best applied to a dedicated process that doesn’t change often.

Logic development

PLC can programmed be programmed based on our application.

DCS comes with built-in control functions

Cost of DCS is high

PLC or DCS Which is Right for Your Operation?

Комментарии

0:02:45

0:02:45

0:04:54

0:04:54

0:11:23

0:11:23

0:07:13

0:07:13

0:07:17

0:07:17

0:08:29

0:08:29

0:09:16

0:09:16

0:11:03

0:11:03

0:34:35

0:34:35

0:12:10

0:12:10

0:01:07

0:01:07

0:03:22

0:03:22

0:06:31

0:06:31

0:07:06

0:07:06

0:08:34

0:08:34

0:01:48

0:01:48

0:00:57

0:00:57

0:00:28

0:00:28

0:03:25

0:03:25

0:01:39

0:01:39

0:15:11

0:15:11

0:20:32

0:20:32

0:02:54

0:02:54

0:04:09

0:04:09