filmov

tv

How a TURBOJET Engine works - Explained by CAPTAIN JOE

Показать описание

🚀 Support my educational mission & get access to exclusive content & Zooms on Patreon!

✈️ Want to become a pilot? Start your journey with The Future Pilot Masterclass

📖 Level up your skills & mindset with my book, "READ and DO"

📸 Join my Instagram crew for extra insights!

🌍 Still curious? Explore more at

——————————————————————————————————

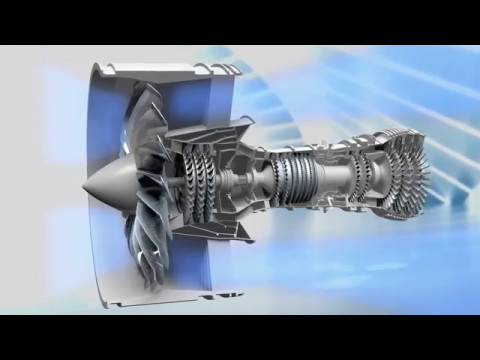

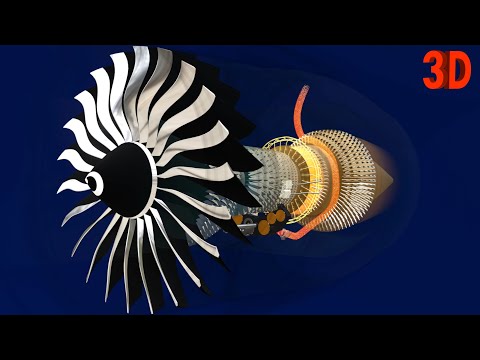

Welcome to the series about Jet Engines! In this first of three videos we dive into the mechanics and science behind the turbojet engine! We’ll break down the components of a turbojet engine and look at the thermodynamic principles that make an engine running.

Make sure to subscribe and hit the notification bell so you don’t miss our upcoming episodes on turbofan engines and afterburners! Join me on this exciting journey into aviation engineering!

Huge thanks for the permissions to use these Videos:

@AgentJayZ

@XOrionFE

@PaddyPatrone

Intro Song:

Outro Song:

ALL COPYRIGHTS TO THIS VIDEO ARE OWNED BY FLYWITHCAPTAINJOE.COM ANY COPYING OR ILLEGALLY DOWNLOADING AND PUBLISHING ON OTHER PLATFORMS WILL FOLLOW LEGAL CONSEQUENCES

00:00 Intro

00:40 General Information

01:11 History of the Turbojet engine

02:30 Composition and parts

04:22 Thermodynamics

10:55 Internals of the compressor

15:16 Combustion chamber

17:03 Turbine work

18:44 Final words and outro

✈️ Want to become a pilot? Start your journey with The Future Pilot Masterclass

📖 Level up your skills & mindset with my book, "READ and DO"

📸 Join my Instagram crew for extra insights!

🌍 Still curious? Explore more at

——————————————————————————————————

Welcome to the series about Jet Engines! In this first of three videos we dive into the mechanics and science behind the turbojet engine! We’ll break down the components of a turbojet engine and look at the thermodynamic principles that make an engine running.

Make sure to subscribe and hit the notification bell so you don’t miss our upcoming episodes on turbofan engines and afterburners! Join me on this exciting journey into aviation engineering!

Huge thanks for the permissions to use these Videos:

@AgentJayZ

@XOrionFE

@PaddyPatrone

Intro Song:

Outro Song:

ALL COPYRIGHTS TO THIS VIDEO ARE OWNED BY FLYWITHCAPTAINJOE.COM ANY COPYING OR ILLEGALLY DOWNLOADING AND PUBLISHING ON OTHER PLATFORMS WILL FOLLOW LEGAL CONSEQUENCES

00:00 Intro

00:40 General Information

01:11 History of the Turbojet engine

02:30 Composition and parts

04:22 Thermodynamics

10:55 Internals of the compressor

15:16 Combustion chamber

17:03 Turbine work

18:44 Final words and outro

Комментарии

0:19:55

0:19:55

0:05:01

0:05:01

0:05:21

0:05:21

0:03:05

0:03:05

0:03:13

0:03:13

0:03:58

0:03:58

0:13:23

0:13:23

0:00:31

0:00:31

0:00:55

0:00:55

0:00:44

0:00:44

0:08:40

0:08:40

0:11:47

0:11:47

0:12:21

0:12:21

0:03:57

0:03:57

0:00:53

0:00:53

0:00:11

0:00:11

0:05:55

0:05:55

0:03:42

0:03:42

0:08:08

0:08:08

0:00:14

0:00:14

0:00:32

0:00:32

0:00:31

0:00:31

0:00:38

0:00:38

0:01:00

0:01:00