filmov

tv

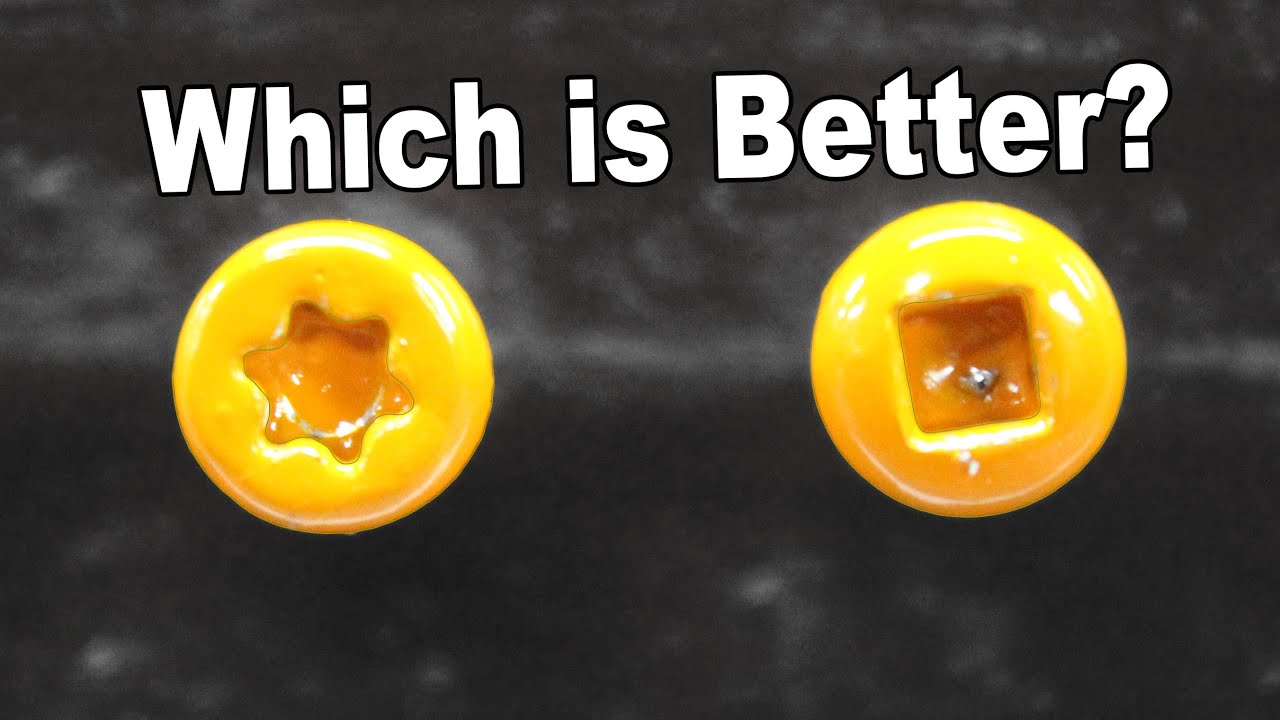

Pocket Hole Screws: STAR vs SQUARE

Показать описание

When it comes to pocket hole screws, they are great to use, but I usually have a few that want to cam out, which can be very annoying. So I try to find an alternative to the standard square head screws. And here are the results.

If you would like to help support our channel, please use our affiliate page on Amazon (paid link), were we have listed a bunch of items we suggest.

Just follow this link:

Amazon Product Suggestions:

(There is NO extra cost to you.)

Use of video content for personal projects is at your own risk.

Your results may vary depending on type of materials, your craftsmanship, and tools at hand. We are not responsible for any damages or injuries that might occur.

Some links in description are affiliate links that let you help support our channel at no extra cost to you.

Matthew 2:10

#pocketholes #woodworking #build

If you would like to help support our channel, please use our affiliate page on Amazon (paid link), were we have listed a bunch of items we suggest.

Just follow this link:

Amazon Product Suggestions:

(There is NO extra cost to you.)

Use of video content for personal projects is at your own risk.

Your results may vary depending on type of materials, your craftsmanship, and tools at hand. We are not responsible for any damages or injuries that might occur.

Some links in description are affiliate links that let you help support our channel at no extra cost to you.

Matthew 2:10

#pocketholes #woodworking #build

Pocket Hole Screws: STAR vs SQUARE

Milescraft - Advantages Of Industry-Leading TORX® / Star Drive Pocket Screws

Pocket Holes / Pocket Screws EXPLAINED!! (How Pocket Joinery Works--Kreg Pocket Jigs--PROS AND CONS)

Milescraft 1327 PocketJig400 – Self-Clamping, Heavy-Duty, All-Metal Pocket Hole Jig

Torx screws vs Robertson screws -- First Impressions (WnW #53)

You're being misled about woodworking joinery

How to Drill Pocket Hole WITHOUT Jig

Pocket Holes on the Run with Milescraft

China Tools Ep.37. I Wish I had seen this video before buying a Pocket Hole Jig!

How to ● Cheapest Way to Fill a KREG JIG pocket hole

Why are Pozidriv screws better than Phillips?

Kreg Pocket Hole Jig | Pistol Grip | Finish Carpentry Review

What Is A Robertson Screw? (For Non-Canadians) EthAnswers

Screwdriver | Technology video#8

China Tools Episode 16, Pocket hole jig and Hinge jig.

Replaced My KREG Pocket Jig With MILESCRAFT Pocket Jig 400, and here's why

Kreg Jig Upgrade - Quick & Easy Jig

Milescraft 1324 PocketJig100, Single Barrel Pocket Jig - How to Make Pocket Holes

Soft close hinge | How to install | Easy installation #shorts

What kind of screw should I use? Woodworking Basics

The brand new pocket hole jig from Milescraft #woodworking #foryou #tools #woodwork

Milescraft 7336 Pocket Jig 200XCJ - Pocket Hole Bundle with Double Barrel Pocket Hole Jig

The SECRET to DIY Pocket Holes! 🤯

ENJOYWOOD XK4 Pocket Hole Jig Kit Aluminum Alloy Adjustable Woodworking Drilling Guide Review

Комментарии

0:05:48

0:05:48

0:02:21

0:02:21

0:06:45

0:06:45

0:02:46

0:02:46

0:09:47

0:09:47

0:11:55

0:11:55

0:00:55

0:00:55

0:04:02

0:04:02

0:15:58

0:15:58

0:02:34

0:02:34

0:11:07

0:11:07

0:06:11

0:06:11

0:02:34

0:02:34

0:00:21

0:00:21

0:18:19

0:18:19

0:07:14

0:07:14

0:09:45

0:09:45

0:01:34

0:01:34

0:00:11

0:00:11

0:13:45

0:13:45

0:00:23

0:00:23

0:01:33

0:01:33

0:02:34

0:02:34

0:02:10

0:02:10