filmov

tv

Do Not Install Underfloor Heating With a Heat Pump Before Watching This Video

Показать описание

#heatpump #ufh #heating

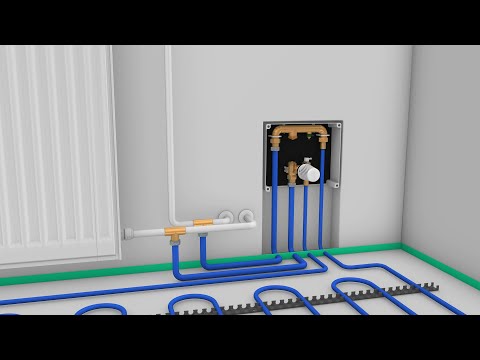

In this video, we are looking at a heat pump installation in a high heat loss property with an underfloor heating system from Jupiter.

In this video, we are looking at a heat pump installation in a high heat loss property with an underfloor heating system from Jupiter.

Do Not Install Underfloor Heating With a Heat Pump Before Watching This Video

Your Underfloor Heating Could Be Better - Here Is How.

Underfloor Heating — The 2 Big Questions

Which Underfloor Heating Solution Is Best For You?

TO DIY OR NOT DIY!?!? | Underfloor Heating & Insulation

How to Install Low Profile Underfloor Heating ~ ProWarm LoFlo

When underfloor heating is not installed properly and floats

Underfloor heating actuators. Avoid mistakes. Tips and tricks!

Underfloor heating in a suspended wood floor | Insulation | Screed

Underfloor Heating without removing the Screed

How to Install Underfloor Heating in an Old Property

TorFloor Suspended Underfloor Heating from Omnie

This is why you should install underfloor heating

Retrofit Low Profile Underfloor Heating - DIY Kit for Installation on Clip Rails | FLEXIRO

D.I.Y Underfloor Heating - Don't get cold feet !

How to test underfloor heating

How to Lay and Install Underfloor Heating #underfloorheating #howto

UNDERFLOOR HEATING WIRING PROBLEM SOLVING || UK ELECTRICIAN ||

Step-by-Step Guide to Setting Up an Underfloor Heating Manifold

Connecting a floor sensor to an electric underfloor heating thermostat

Installing underfloor heating in an old suspended floor

Best Affordable Heated Floor System...Save TONS of MONEY!

Retro Fit Underfloor Heating Solution for Vinyl, Carpet and Linoleum.

How to fit underfloor heating #shorts #howto

Комментарии

0:16:38

0:16:38

0:12:17

0:12:17

0:08:51

0:08:51

0:07:27

0:07:27

0:10:54

0:10:54

0:21:24

0:21:24

0:00:43

0:00:43

0:03:35

0:03:35

0:02:53

0:02:53

0:02:09

0:02:09

0:28:36

0:28:36

0:08:52

0:08:52

0:01:28

0:01:28

0:02:49

0:02:49

0:00:33

0:00:33

0:01:03

0:01:03

0:03:29

0:03:29

0:21:01

0:21:01

0:14:32

0:14:32

0:00:25

0:00:25

0:00:12

0:00:12

0:07:16

0:07:16

0:00:41

0:00:41

0:00:24

0:00:24