filmov

tv

Your Underfloor Heating Could Be Better - Here Is How.

Показать описание

#UFH #underfloorheating #radiantheating

In this video, I show you how to bring your underfloor heating to a modern standard and how to make sure it will be compatible with a heat pump in the future.

In this video, I show you how to bring your underfloor heating to a modern standard and how to make sure it will be compatible with a heat pump in the future.

Your Underfloor Heating Could Be Better - Here Is How.

Increasing Zone Flow Rates

Underfloor heating mixing valve #underfloorheating #heatpump

Pressure Testing Your Underfloor Heating System

Filling And Venting Your UFH Manifold

Which Underfloor Heating Solution Is Best For You?

YOUR Underfloor Heating questions answered with Polypipe

Can heat pumps be used with UFH? | Polypipe Underfloor Heating

How to test underfloor heating

Electric Underfloor Heating Installation - priMo Bathrooms - Ant priMo

Step-by-Step Guide to Setting Up an Underfloor Heating Manifold

DIY Fix for Underfloor Heating Dead Zones

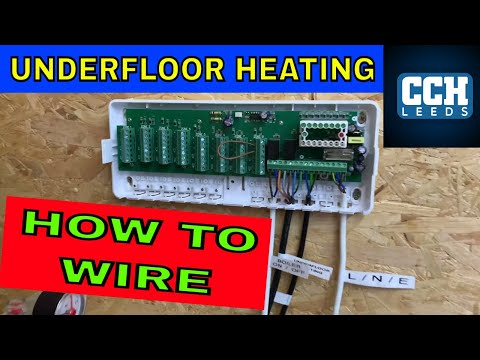

Plumbing - How To Wire Underfloor Heating - Wet Underfloor Heating

Retro fitting Underfloor Heating - Wunda Rapid Response Overfloor solution - get your FREE estimate

PT8 Water underfloor heating #diy #underfloorheating #diyhomerenovation #homeimprovement #renovation

Is It Better To Leave The Heating On Constantly? Boilers & Heat Pumps | Consumer Advice

Underfloor Heating — The 2 Big Questions

How to install radiant floor heat #dvvbel

Hydronic underfloor heating installation 🔥 #renovation #home #construction #shorts

STOP SCROLLING! This Underfloor Heating Hack Will Blow Your Mind! #shorts #youtube #2024 #subscribe

Do I need underfloor heating or can I keep my radiators?

How under floor heating systems can add value to your home!

Power flush & new underfloor heating system installation in North London

GETTING UNDERFLOOR HEATING WORKING PROPERLY... (Can i sort it)

Комментарии

0:12:17

0:12:17

0:00:55

0:00:55

0:00:17

0:00:17

0:06:30

0:06:30

0:06:56

0:06:56

0:07:27

0:07:27

0:13:48

0:13:48

0:00:38

0:00:38

0:01:03

0:01:03

0:00:34

0:00:34

0:14:32

0:14:32

0:06:34

0:06:34

0:05:46

0:05:46

0:00:42

0:00:42

0:01:00

0:01:00

0:16:15

0:16:15

0:08:51

0:08:51

0:00:35

0:00:35

0:00:09

0:00:09

0:00:13

0:00:13

0:13:06

0:13:06

0:00:22

0:00:22

0:00:14

0:00:14

0:19:41

0:19:41