filmov

tv

Simple Modular Work Tables (WITH MAGNETS!) // Woodworking How To | I Like To Make Stuff

Показать описание

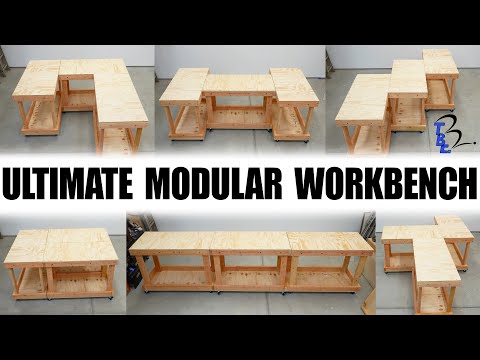

For my new shop, I made some simple, sturdy and super modular work tables WITH MAGNETS!!! Tables, UNITE!

TOOLS & SUPPLIES:

It's finally time to start setting up my new shop! Everything is still shoved against the walls, mostly still in boxes and completely unorganized. As a first step towards making the space usable, I decided to build a work table. I debated about making one large 4x8 table that could act as an out feed table for my table saw. I was worried that such a large item would start to eat up my large open space as I really want to try to keep this shop as open and flexible as possible. On my Twitch livestream recently, I opened up the discussion for input about how to make a table more useful and modular. We had an AWESOME collaborative design session and eventually the project turned into tables, not just table.The idea we ended up with was multiple tables that could snap together (using magnets) to create a large 4x8 table when necessary, or split apart to be useful in different places or configurations. They turned out to be really simple, really sturdy and super cool :)

Learn 3d modeling, get digital plans, and cool merch at

Want to support ILTMS? Get exclusive content and more...

FOLLOW:

#ILikeToMakeStuff

About I Like To Make Stuff:

We have lots of projects including woodworking, metalworking, electronics, 3D printing, prop making and more!

These videos are our attempt inspire and empower others to make the stuff that they want to have. Hopefully you'll see something here that will inspire you to make something that you're passionate about!

Simple Modular Work Tables (WITH MAGNETS!) // Woodworking How To | I Like To Make Stuff

I Like To Make Stuff

TOOLS & SUPPLIES:

It's finally time to start setting up my new shop! Everything is still shoved against the walls, mostly still in boxes and completely unorganized. As a first step towards making the space usable, I decided to build a work table. I debated about making one large 4x8 table that could act as an out feed table for my table saw. I was worried that such a large item would start to eat up my large open space as I really want to try to keep this shop as open and flexible as possible. On my Twitch livestream recently, I opened up the discussion for input about how to make a table more useful and modular. We had an AWESOME collaborative design session and eventually the project turned into tables, not just table.The idea we ended up with was multiple tables that could snap together (using magnets) to create a large 4x8 table when necessary, or split apart to be useful in different places or configurations. They turned out to be really simple, really sturdy and super cool :)

Learn 3d modeling, get digital plans, and cool merch at

Want to support ILTMS? Get exclusive content and more...

FOLLOW:

#ILikeToMakeStuff

About I Like To Make Stuff:

We have lots of projects including woodworking, metalworking, electronics, 3D printing, prop making and more!

These videos are our attempt inspire and empower others to make the stuff that they want to have. Hopefully you'll see something here that will inspire you to make something that you're passionate about!

Simple Modular Work Tables (WITH MAGNETS!) // Woodworking How To | I Like To Make Stuff

I Like To Make Stuff

Комментарии

0:14:17

0:14:17

0:15:13

0:15:13

0:15:40

0:15:40

0:00:33

0:00:33

0:00:15

0:00:15

0:01:00

0:01:00

0:21:10

0:21:10

0:08:48

0:08:48

0:00:29

0:00:29

0:00:59

0:00:59

0:34:46

0:34:46

0:21:51

0:21:51

0:00:19

0:00:19

0:18:18

0:18:18

0:00:11

0:00:11

0:12:38

0:12:38

0:00:05

0:00:05

0:01:00

0:01:00

0:11:23

0:11:23

0:11:13

0:11:13

0:00:07

0:00:07

0:16:52

0:16:52

0:08:40

0:08:40

0:00:16

0:00:16