filmov

tv

Manufacturing Work Cell Optimization: Design, Layout and Cycle Time Analysis

Показать описание

Manufacturing Work Cell Optimization: Design, Layout and Cycle Time Analysis

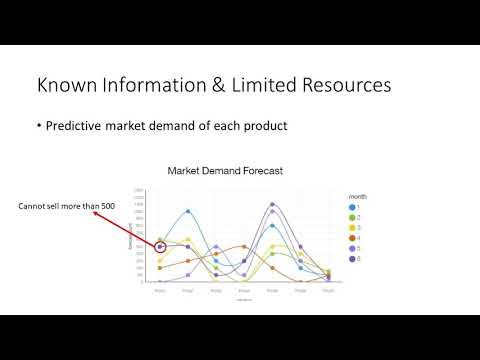

Manufacturing & Assembly Cell Optimization Analysis

How to design a Lean Layout/Obeyaka? The Lean Manufacturing Guide

10 Rules of Lean Assembly Cell Design

Cellular Manufacturing: What It Is And Why It Matters

How Toyota Changed The Way We Make Things

Simulation Model for facility layout Optimization

Manufacturing Optimization

What is Placement in VLSI Physical Design?

Design Optimization

Five Steps For Ergonomic Workstation Design

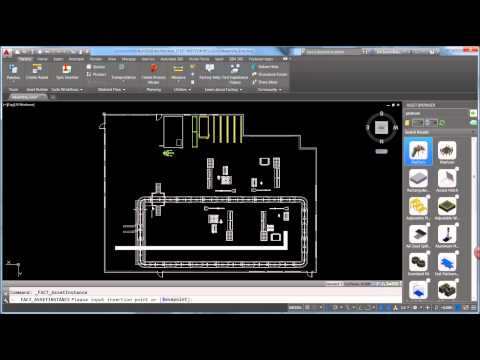

Factory Layout Optimization for AutoCAD

Optimization and Planning for Factories in Manufacturing

Field Optimization A Modular Design Tool for Advanced Manufacturing Justin Hattendorf - nTop - CDFAM

Production Optimization

Production Optimization Simulation

Design Optimization & Additive Manufacturing

Manufacturing-Ready DfAM Optimization - Design process automation for additive manufacturing

Factory Layout Design - Part 1 of 4 (AutoCAD)

Optimization Challenges in Manufacturing

Daniel Badillo Podcast - Work Cell Optimization

Production Optimization Consulting

Optimization of Robotic Cells

Cellular Manufacturing and One Piece Flow

Комментарии

0:09:48

0:09:48

0:35:31

0:35:31

0:15:21

0:15:21

0:04:15

0:04:15

0:02:32

0:02:32

0:04:52

0:04:52

0:01:58

0:01:58

0:01:23

0:01:23

0:43:48

0:43:48

0:00:14

0:00:14

0:03:13

0:03:13

0:00:35

0:00:35

0:04:03

0:04:03

0:19:10

0:19:10

0:00:26

0:00:26

0:02:39

0:02:39

0:00:55

0:00:55

0:44:41

0:44:41

0:01:18

0:01:18

0:27:37

0:27:37

0:11:46

0:11:46

0:01:14

0:01:14

0:04:39

0:04:39

0:03:34

0:03:34